2022 Good Quality Margarine Production Process - Shortening/Ghee Production Line China Manufacturer – Shipu

2022 Good Quality Margarine Production Process - Shortening/Ghee Production Line China Manufacturer – Shipu Detail:

Shortening & Ghee Production Line

Shortening and Ghee are very popular in the bakery industry,the raw material include palm oil, vegetable oils, animal fat, partially hydrogenated oils and fats, marine oils, palm kernel oil, lard, beef tallow, palm stearin, coconut oil, etc.

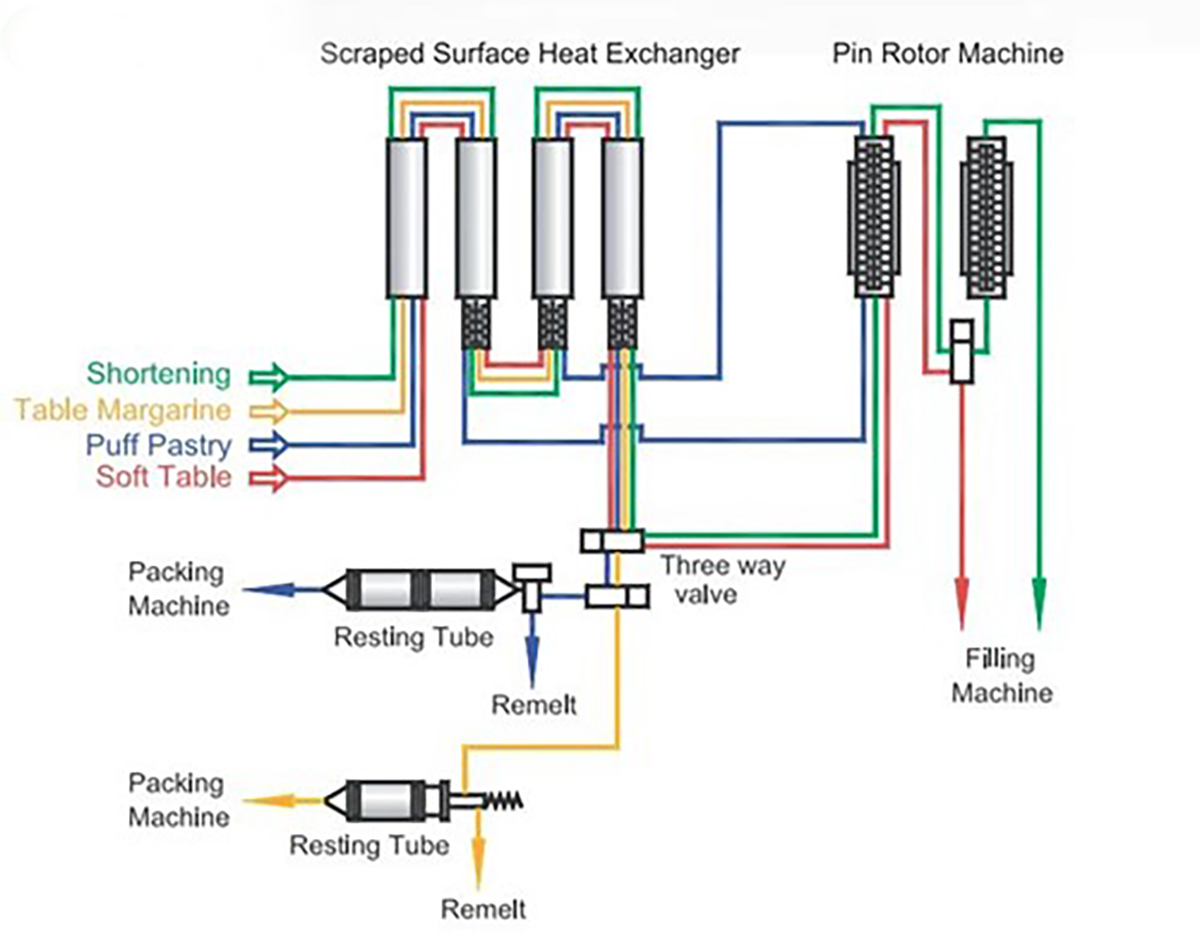

The main shortening production process are Measuring——Ingredients Proportion——Filtration——Emulsification——Crystallization——Pin Rotor Kneading——Filling & Packing. The equipment that makes up the Shortening production plant includes the Votators, Scraped Surface Heat Exchanger, Kneader, Pin Rotor, shortening filling and packing machine, homogenizer, emulsifying tank, batching tank, high pressure pump, sterilizer, refrigeration compressor, refrigeration unit, cooling tower, etc.

Where, SPA + SPB + SPC units or SPX-Plus + SPB + SPCH units forms a shortening crystallization line, which can produce shortening, vegetable ghee and other butter products.

The structure of SPA Series SSHE Shortening making machine is unique. After many years optimization, it has high equipment stability, the fineness and finish of the shortening products are leading in China.

In general, SP series margarine/shortening(ghee) production process is:

1. Oil and Fat blends and aqueous phase are pre-weighed in two emulsion holding and mixing vessels. Blending in o the holding/ mixing vessels is done by load cells controlled by PLC control system.

2. Blending processing is controlled by logical computer with touch screen. Each mixing/production tank is equipped with high shear mixer to emulsify the oil and aqueous phases.

3. The mixer is equipped with variable speed drive to reduce the speed for gentle agitation after emulsification is done. The two tanks will be used as production tank and emulsification tank alternatively.

4. The production tank will also function as any product recycle from the production line. The production tank will be the water/chemical tank for the line cleaning and sanitation.

5. The emulsion from the production tank will pass through a twin filter/strainer to ensure no solid will pass in o the final product (GMP requirement).

6. The filter/strainer operates alternatively for filter cleaning. The filtered emulsion is then passed through a pasteurizer (GMP requirement) which consists of three sections of two plate heaters and one retention pipe.

7. The first plate heater will heat the oil emulsion up to pasteurization temperature prior to passing through the retention pipe to provide the necessary holding time.

8. Any emulsion heat to less than the required pasteurization temperature will be recycled back to the production tank.

9 The pasteurized oil emulsion will enter in o the cooling plate heat exchanger to cool down to approximate 5 ~ 7-degree C above the oil melting point to minimize chilling energy.

10. The plate heater is heated by hot water system with temperature control. The plate cooling is done by cooling tower water with automatic temperature regulation valve and PID loops.

11. The emulsion pumping/transfer, up to this point, is done by one high pressure pump. The emulsion is fed into Votator unit and pin rotor in different orders, then lower the temperature to the desired exit temperature for produce the margarine/shortening products needed.

12. The semi-solid oil coming out of the votator machine will be packing or filling by the margarine shortening filling and packaging machine.

Best price of Votators

Since the year of 2004, ShiPU Machinery has been focusing on the field of scraped surface heat exchangers. Our scraped surface heat exchangers have a very high reputation and reputation in the Asia market. Shipu Machinery has long time offered the best price machines to the bakery industry, food industry and the dairy product industry, like Fonterra group, Wilmar group, Puratos, AB Mauri and etc. Our scraper heat exchangers price is only about 20%-30% of similar products in Europe and America, and is welcomed by many factories. The manufacturing plant uses the good-quality and inexpensive SP series scraped surface heat exchangers made in China to rapidly increase production capacity and reduce production costs, the Goods produced by their factory have excellent market competitiveness and cost advantages, quickly occupied most market share.

Food manufacturers from all over the world are welcome to purchase scraper heat exchangers directly from SP Machinery, and related equipment manufacturers, installation and engineering companies are also welcome to apply to become our brand agents. We provide good-quality and cheap scraped surface heat exchanger with the best price.

Site Commissioning

Product detail pictures:

Related Product Guide:

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for 2022 Good Quality Margarine Production Process - Shortening/Ghee Production Line China Manufacturer – Shipu , The product will supply to all over the world, such as: Greece, India, New Orleans, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.