8 Year Exporter Shortening Making Machine - SP Series Starch/Sauce Processing Line China Factory – Shipu

8 Year Exporter Shortening Making Machine - SP Series Starch/Sauce Processing Line China Factory – Shipu Detail:

SP Series Starch/Sauce Processing Line

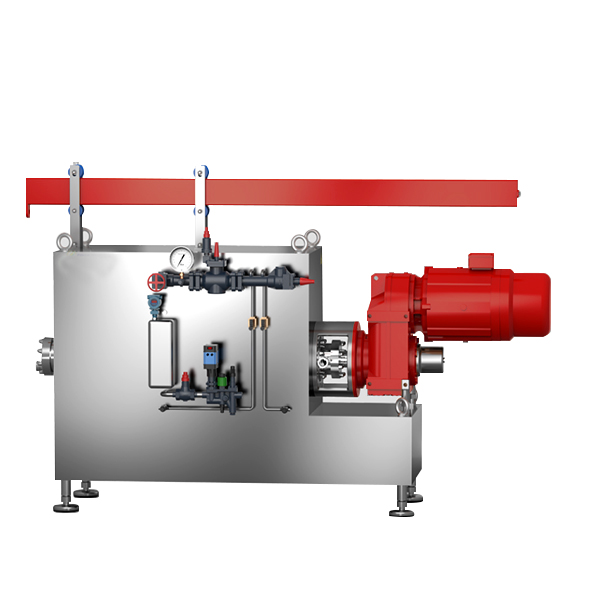

Many prepared foods or other products do not achieve optimal heat transfer due to their consistency. For example, starch, sauce, bulky, sticky, sticky or crystalline products contained in food products, can quickly clog or foul certain parts of the heat exchanger. The advantage scrap surface heat exchanger incorporates special designs that make it a model heat exchanger for heating, or cooling these products that damage heat transfer.

As the product is pumped in o the votator heat exchanger material barrel, the rotor and scraper unit ensures an even temperature distribution, scraping the material away from the heat exchange surface while continuously and gently mixing the product.

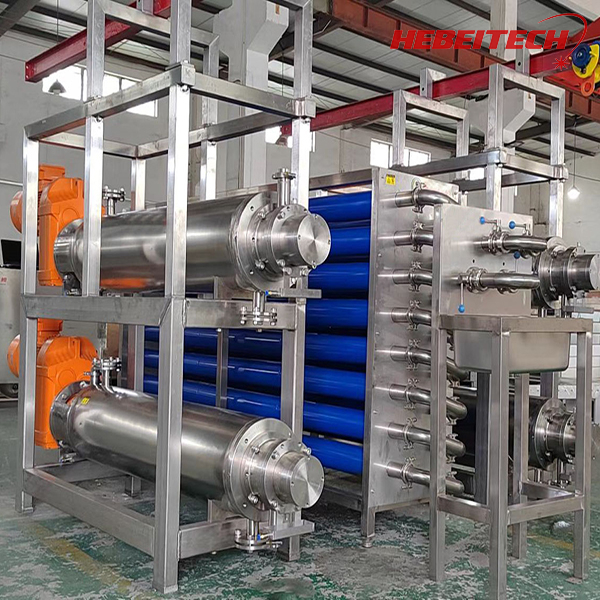

The SP series starch cooking system consists of a heating section, a heat preservation section and a cooling section. Depending on the output, configure a single or multiple scrap heat exchangers. After the starch slurry is batched in the batching tank, it is pumped in o the cooking system through the feeding pump. The SP series votator heat exchanger used steam as a heating medium to heat the starch slurry from 25°C to 85°C, whereupon, the starch slurry was kept in the holding section for 2 minutes. The material was cooled from 85°C to 65°C by SSHEs as a cooling device and using ethylene glycol as a cooling medium. The cooled material goes to the next section. The whole system can be cleaned by CIP or SIP to ensure the hygienic index of the whole system.

Site Commissioning

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for 8 Year Exporter Shortening Making Machine - SP Series Starch/Sauce Processing Line China Factory – Shipu , The product will supply to all over the world, such as: Bandung, Sierra Leone, Kuwait, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!