Excellent quality Scrape Surface Heat Exchanger - Scraped Surface Heat Exchanger Model SPX-PLUS China Supplier – Shipu

Excellent quality Scrape Surface Heat Exchanger - Scraped Surface Heat Exchanger Model SPX-PLUS China Supplier – Shipu Detail:

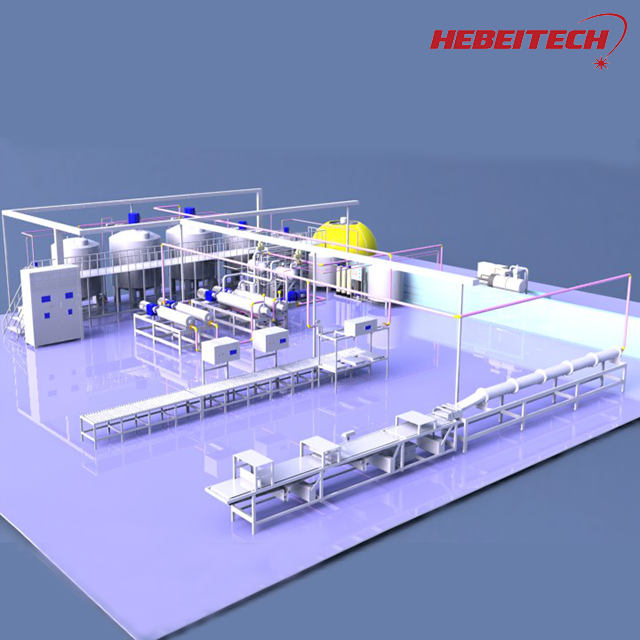

China Scraped Surface Heat Exchanger & Votator Manufacturer and Supplier.Our company has China Scraped Surface Heat Exchanger & Votator on sale, welcome to contact us.

Application

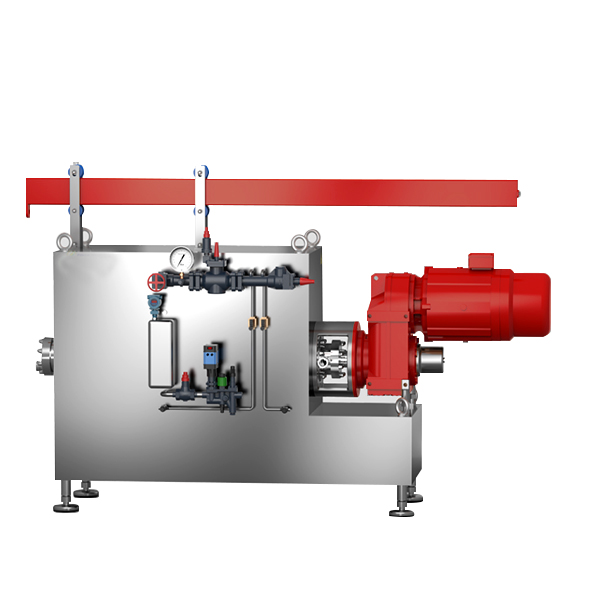

SPX-Plus series scraped surface heat exchanger is specially designed for high viscosity food industry,It is especially suitable for food manufacturers of puff pastry margarine, table margarine and shortening. It has excellent cooling capacity and excellent crystallization capacity. It integrates Ftherm® liquid level control refrigeration system, Hantech evaporation pressure regulation system and Danfoss oil return system. It is equipped with 120bar pressure resistant structure as standard, and the maximum equipped motor power is 55kW, it is suitable for the continuous production of fat and oil products with viscosity up to1000000 cP.

Similar Competitive Machines

The international competitors of SPX-plus SSHEs are Perfector series, Nexus series and Polaron series SSHEs under gerstenberg, Ronothor series SSHEs of RONO company and Chemetator series SSHEs of TMCI Padoven company.

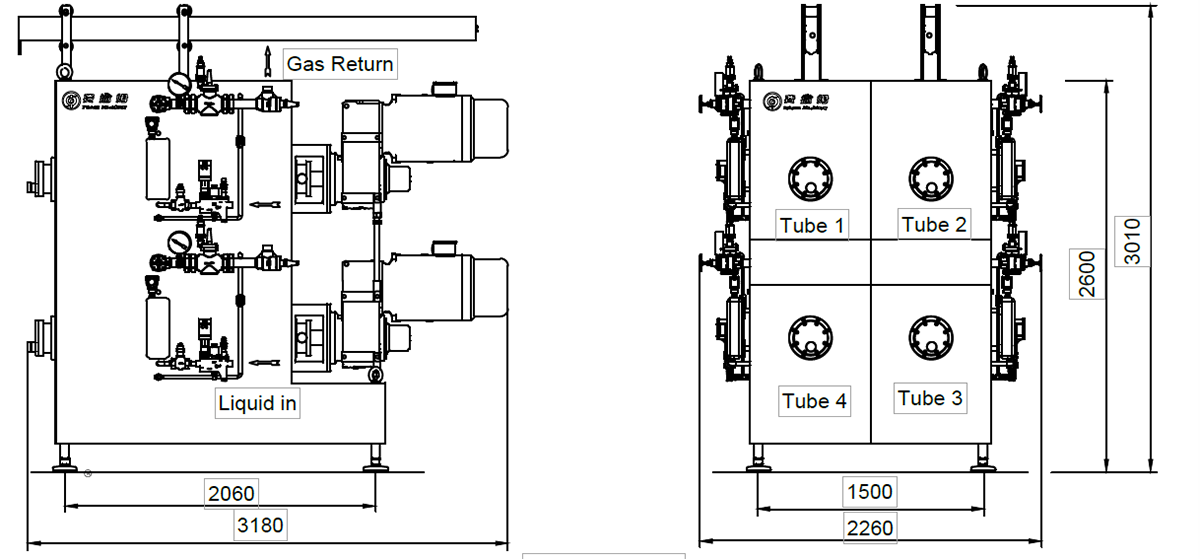

Technical Specification

| Plus Series | 121AF | 122AF | 124AF | 161AF | 162AF | 164AF |

| Nominal Capacity Puff Pastry Margarine @ -20°C (kg/h) | N/A | 1150 | 2300 | N/A | 1500 | 3000 |

| Nominal Capacity Table Margarine @-20°C (kg/h) | 1100 | 2200 | 4400 | 1500 | 3000 | 6000 |

| Nominal Capacity Shortening @-20°C (kg/h) | 1500 | 3000 | 6000 | 2000 | 4000 | 8000 |

| Number of Refrigerant circuits | 1 | 2 | 4 | 1 | 2 | 4 |

| Number of Tubes per Refrigerant circuit | 1 | 1 | 1 | 1 | 1 | 1 |

| Motor for Puff Pastry Margarine (kw) | N/A | 22+30 | 18.5+22+30+37 | 37+45 | 30+37+45+55 | |

| Motor for Table Margarine (kw) | 18.5 | 18.5+18.5 | 18.5+18.5+22+22 | 30 | 22+30 | 22+30+37+45 |

| Motor for Shortening (kw) | 18.5 | 18.5+18.5 | 18.5+18.5+22+22 | 30 | 22+30 | 22+22+30+30 |

| Number of Gear Box | 1 | 2 | 4 | 1 | 2 | 4 |

| Cooling Surface per Tube (m2) | 0.61 | 0.61 | 0.61 | 0.84 | 0.84 | 0.84 |

| Annular Space (mm) | 10 | 10 | 10 | 10 | 10 | 10 |

| Capacity @ -20°C (kw) | 50 | 100 | 200 | 80 | 160 | 320 |

| Max. Working Pressure @ Media Side (Bar) | 20 | 20 | 20 | 20 | 20 | 20 |

| Max. Working Pressure @ Product Side (Bar) | 120 | 120 | 120 | 120 | 120 | 120 |

| Min. Working Temperature °C | -29 | -29 | -29 | -29 | -29 | -29 |

| Chilling Tube Dimension (Dia./Length, mm) | 160/1200 | 160/1200 | 160/1200 | 160/1600 | 160/1600 | 160/1600 |

| Product Volume per Tube (L) | 8.6 | 8.6 | 8.6 | 10.5 | 10.5 | 10.5 |

| Product Pipe Inlet/Outlet (mm) | DN50 | DN50 | DN50 | DN50 | DN50 | DN50 |

| Rows of Scraper | 4 | 4 | 4 | 4 | 4 | 4 |

| Nominal Scraper Rotor Speed (rpm) | 340 | 340 | 340 | 240 | 240 | 240 |

| Water Attemperation Capacity (kw) | 6 | 6+6 | 6+6+6+6 | 6 | 6+6 | 6+6+6+6 |

| Water Attemperation Volume (L) | 30 | 30 | 60 | 30 | 30 | 60 |

| Water Circulation Pump (kw) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

Equipment Drawing

Site Commissioning

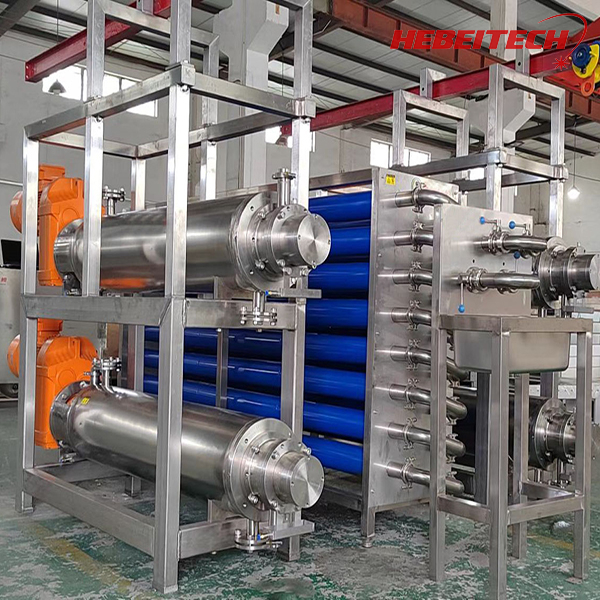

Product detail pictures:

Related Product Guide:

From the past few years, our firm absorbed and digested sophisticated technologies equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted into the growth of Excellent quality Scrape Surface Heat Exchanger - Scraped Surface Heat Exchanger Model SPX-PLUS China Supplier – Shipu , The product will supply to all over the world, such as: Peru, Holland, Philippines, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.