Factory Supply Butter Packaging Machine - Pasteurizer Model SPTP China Supplier – Shipu

Factory Supply Butter Packaging Machine - Pasteurizer Model SPTP China Supplier – Shipu Detail:

Equipment Description

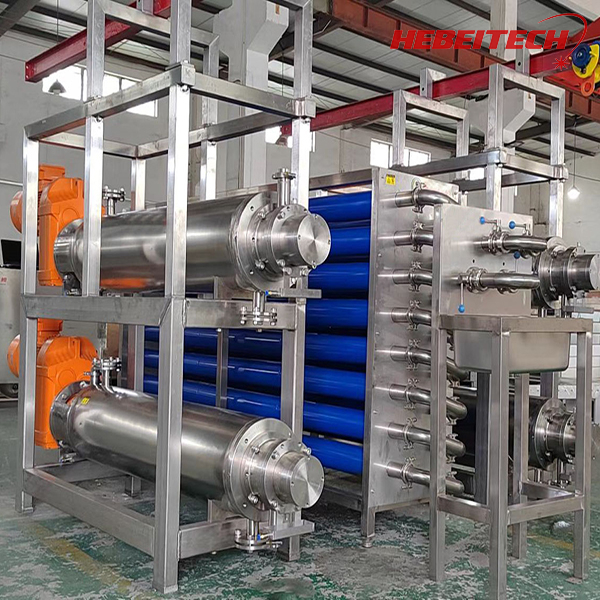

Pasteurizer (Tube heat exchanger) is widely used for sterilization in the oil fat and milk processing industry, the material will be heated up to 75-90 degree, and kept for a short time, about 15-16 seconds, it can kill the pathogenic bacteria, while can keep most of the nutrition ingredient.

Equipment Picture

Equipment Details

Technical Specification

| 1、Working Condition | ||||||||||||||

| Capacity | 0.5-4t/h | Material Inlet | 50℃ | Steam Pressure | 0.6MPa | |||||||||

| 2、Design Requirement | ||||||||||||||

| Material Sterilization Temperature | 75℃ | Holding Time | 15S | Material Outlet Temperature | 60℃ | |||||||||

| 3、Main Technical Parameters | ||||||||||||||

| Item | Technical Parameter | Item | Technical Parameter | |||||||||||

| Model | SPTP-0.5/4T | Power | 5.5-10.5KW | |||||||||||

| Heat Exchange Area | 38M2 | Product Inlet/Outlet | φ38×1.5mm | |||||||||||

| Product Pipe Material, Diameter | SUS316L、¢12×1 | Cooling Water Inlet/Outlet | φ63×1.5mm | |||||||||||

| Outer Pipe Material, Diameter | SUS304、¢57×2 | Cooling Water Consumption | 9t/h | |||||||||||

| Automatic Control Of Sterilization Temperature | ±1℃ | Steam Pipe Diameter | φ50.8×3mm | |||||||||||

| Cleaning Type | Self CIP System | Steam Consumption | 150Kg/h | |||||||||||

| Compressor Air Consumption | 0.1M3/min | Compressor Air Pressure | 0.6Mpa | |||||||||||

| Weight | 1.6t | Dimensions | 4500×2000×2500 | |||||||||||

| 4、Configuration List | ||||||||||||||

| No | Item | Model Or Specification | Qty | Manufacturer | Remark | |||||||||

| 1 | Main body of tubular heat exchanger | SPTP-0.5/4T | 1 | Hebeitech | ||||||||||

| 2 | Brazed Heat Exchanger | 2M2 | 1 | Hebeitech | ||||||||||

| 3 | Balance Tank | 120L | 1 | Hebeitech | ||||||||||

| 4 | Hot Water Tank | 80L | 1 | Hebeitech | ||||||||||

| 5 | Centrifugal Pump | 10T/50M | 1 | Hebeitech | Power: 4KW | |||||||||

| 6 | Centrifugal Pump | 10T/50M | 1 | Hebeitech | Power: 4KW | |||||||||

| 7 | Hot Water Pump | CDL | 1 | CNP | Power: 2.2KW | |||||||||

| 8 | Steam Regulate Valve | DN32 | 1 | UK Spirax Sarco | ||||||||||

| 9 | Steam Pressure Reducer Valve | DN32 | 1 | UK Spirax Sarco | ||||||||||

| 10 | Steam Plunger Valve | DN32 | 1 | UK Spirax Sarco | ||||||||||

| 11 | Steam Filter | DN32 | 1 | UK Spirax Sarco | ||||||||||

| 12 | Steam Trap | DN25 | 1 | UK Spirax Sarco | ||||||||||

| 13 | Hot Water Back Pressure Valve | Pneumatic Back Pressure Valve | 1 | Hebeitech | ||||||||||

| 14 | Hot Water Switch Valve | Two Position Two Way Pneumatic Valve | 1 | Hebeitech | ||||||||||

| 15 | Constant Pressure Valve | ¢38 | 2 | AFLF/APV/GEA | ||||||||||

| 16 | Two Position Four Way Pneumatic Valve | ¢38 | 2 | AFLF/APV/GEA | ||||||||||

| 17 | Two Position Three Way Pneumatic Valve | ¢38 | 1 | AFLF/APV/GEA | ||||||||||

| 18 | Flow Meter | 0-10T/H | 1 | E+H | ||||||||||

| 19 | Acid And Alkali Diaphragm Pump | P0.29 | 2 | USA Wilden | ||||||||||

| 20 | Electrical Control Box | 304 | 1 | Hebeitech | ||||||||||

| 21 | Electrical Components | Match | 1 | France Schneider | ||||||||||

| 22 | Automatic Temperature Recorder | Match | 1 | Japan Yokogawa | Paperless Recorder | |||||||||

| 23 | Temperature Sensor | Pt100 | 3 | Germany Jumo | ||||||||||

| 24 | Concentrated Acid And Alkali Cylinder | 100L | 2 | Hebeitech | ||||||||||

| 25 | 10 “Color Touch Screen | Match | 1 | Siemens | ||||||||||

| 26 | PLC Program Controller | Match | 1 | Siemens | ||||||||||

| 27 | Frame | 304 | 1 | Hebeitech | ||||||||||

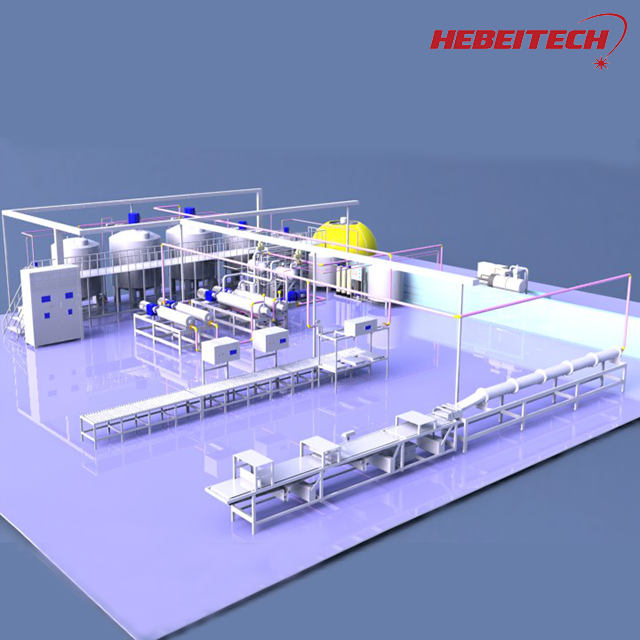

Site Commissioning

Product detail pictures:

Related Product Guide:

We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for Factory Supply Butter Packaging Machine - Pasteurizer Model SPTP China Supplier – Shipu , The product will supply to all over the world, such as: Mumbai, Lyon, Monaco, Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We're doing everything to supply our customers with best services and best solutions . We promise that we are going to be responsible all the way to the end once our services begin.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

Write your message here and send it to us