Fast delivery Pastry Production Line - Margarine Pail Filling Line China Manufacturer – Shipu

Fast delivery Pastry Production Line - Margarine Pail Filling Line China Manufacturer – Shipu Detail:

Equipment Description

产品概述:Product overview:

本机为一头一泵式高精度食用油灌装机。计量精度高,速度快,一经投放市场,立即获得油脂行业知名企业认可。

This machine is a one-pump high-precision edible oil, margarine, shortening, vegetable ghee filling machine. With high measurement accuracy and high speed, once put on the market, it was immediately recognized by well-known enterprises in the oil industry.

- 本机为高精度计量泵式灌装机,利用先进的灌装原理,大大提高了灌装的精确度及稳定性。

This machine is a high-precision metering pump filling machine, which greatly improves the filling accuracy and stability by using the advanced filling principle.

- 一头一泵灌装方式的优点:

Advantages of filling method with one pump at one end:

l 每个灌装头可独立运行。客户可根据自身产量的大小灵活设定需启动的灌装头数。

Each filling head can operate independently. Customers can flexibly set the number of filling heads to be started according to their own output.

l 每个灌装头之间互不影响。也不会因为某个灌装头故障而影响整体灌装的运行(故障灌装头可一键关闭,程序默认关闭后所剩灌装头的个数从而继续工作)。

Each filling head has no influence on each other. It will not affect the whole filling operation because of a certain filling head failure (the failed filling head can be closed with one key, and the number of filling heads left after the program is closed by default so as to continue working).

l 灌装过程中管道压力更稳定。一头一泵方式能使计量精确度得到大幅提高且运行更稳定(传统流量计量方式因最后压力集中到关闭较晚的灌装头而产生计量误差起伏过大或溅油的现象)。

The pipeline pressure is more stable in the filling process. One-pump mode can greatly improve the metering accuracy and make the operation more stable (traditional flow metering mode causes excessive fluctuation of metering error or splash of oil because the final pressure is concentrated to close the filling head later).

- 灌装机外观大方整洁,具有防尘功能,符合食品卫生规范。

The filling machine is elegant and clean in appearance, with dustproof function, and conforms to food hygiene standards.

- 独特的灌装头设计及真空回吸系统完全杜绝了灌装头漏油、滴油、溅油现象。

The unique filling head design and vacuum suction system completely eliminate the phenomenon of oil leakage, dripping and splashing in the filling head.

- 灌装主机自带内置中转罐。

The filling host comes with built-in transit tank.

l 利用液位开关联动供油泵,低于设定值时泵自动启动供油,设备灌装不受原料罐远近、高低等外部条件限制。

The liquid level switch is used to link the oil supply pump. When it is lower than the set value, the pump automatically starts to supply oil. The equipment filling is not limited by external conditions such as the distance and height of the raw material tank.

l 给油液面控制在小范围内浮动,稳定了供料压力,最大程度上减少了液位压力差导致的计量误差,使灌装精度更高。

The liquid level of oil is controlled to float in a small range, which stabilizes the feeding pressure, reduces the metering error caused by the liquid level pressure difference to the greatest extent, and makes the filling accuracy higher.

l 内置中转罐加一头一泵的内置动力,使空罐更为便捷,最大程度上减少了不同品种油品的混油现象。工作完毕,勿须扫线。

The built-in transfer tank and the built-in power of one pump make the empty tank more convenient, and reduce the oil mixing phenomenon of different kinds of oil products to the greatest extent. After work, do not sweep the line.

- 本机自带储气罐并配备压力开关,有效保证整机供气,当显示气压值低于设定值时,油嘴将不会开启,避免因压力不稳定造成误报修。

This machine is equipped with a gas storage tank and a pressure switch, which can effectively guarantee the whole machine’s gas supply. When the displayed air pressure value is lower than the set value, the oil nozzle will not be opened, so as to avoid false repair report caused by unstable pressure.

- 采用机械式操作,特制的升降装置可以精确定位排列不齐的空瓶,保证灌装时油嘴和瓶口位置一致,定位准确。

Mechanical operation is adopted, and the special lifting device can accurately position the empty bottles with irregular arrangement, so as to ensure that the position of the nozzle and the bottle mouth is consistent and the positioning is accurate during filling.

- 采用触摸屏人机界面,操作简捷, PLC控制系统,运算速度快,性能稳定。

Touch screen man-machine interface, simple operation, PLC control system, fast operation speed and stable performance.

- 灌装机自带温度显示器,可以使工作人员实时了解所灌装油品的温度。

The filling machine has its own temperature display, which can make the staff know the temperature of the filled oil in real time.

- 一键转换灌装规格。灌装机内部独特的高人性化配方设定,方便用户预设存储不同灌装规格。每种规格参数据均采用配方功能存入电脑,更换规格灌装时无需再校验参数,直接按相对应“配方键”一键即可转换灌装规格,操作简单,实用。

One-click conversion of filling specifications. The unique and highly humanized formula setting inside the filling machine is convenient for users to preset and store different filling specifications. Each specification data is stored in the computer by formula function. When changing the specification and filling, there is no need to check the parameters. The filling specification can be changed by pressing the corresponding “formula key” directly. The operation is simple and practical.

- 设备自身有自动校对灌装量功能,如计量有误差,输入错误重量数据,电脑即可自动计算正确数据自动校正,无需人工计算输入。

The equipment itself has the function of automatic calibration of filling quantity. If there is an error in measurement and wrong weight data is input, the computer can automatically calculate the correct data and automatically correct it, without manual calculation and input.

- 灌装机特制油嘴接油槽。每日工作结束关闭电源后,接油槽自动弹出,接住油嘴滴下的残油,有效地保证设备清洁、卫生。

12. Filling machine special oil nozzle oil tank. After the power supply is turned off at the end of work every day, the oil receiving tank will automatically pop up to catch the residual oil dripping from the nozzle, thus effectively ensuring the cleanliness and hygiene of the equipment.

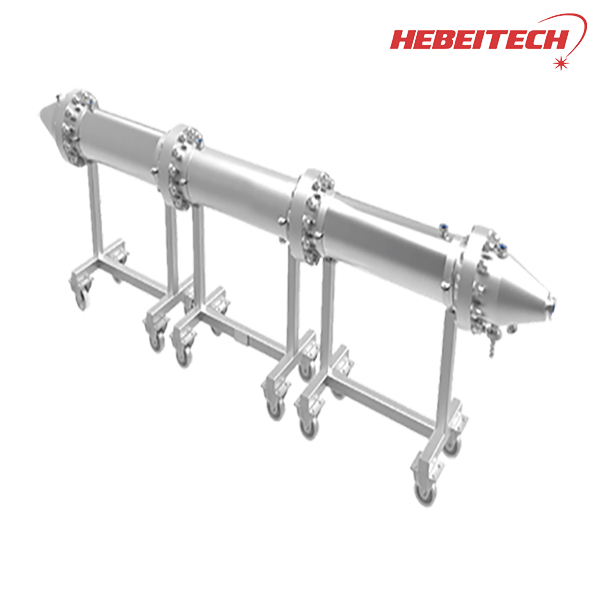

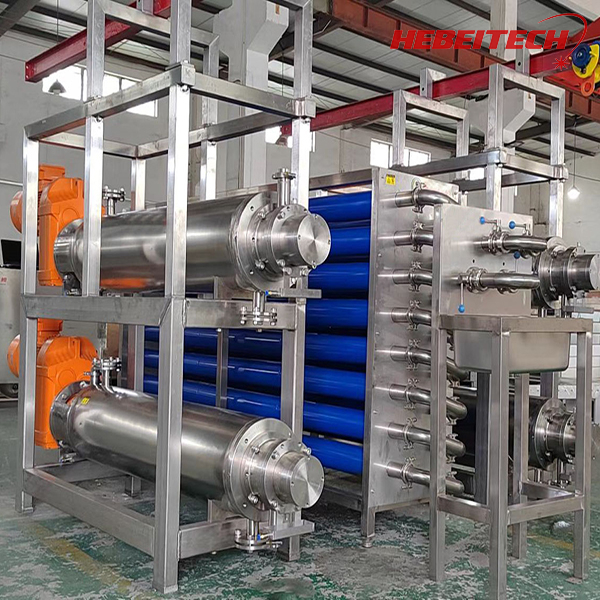

Accessary Equipment

| 主要配件

Main accessories |

主要介绍

Introduction |

| 灌装头

Filling head |

The filling head is a self-developed split structure, that is, the filling head and the cylinder are connected in vitro. This structure can be disassembled and replaced separately, and it is convenient to maintain.

The standard parts are selected to facilitate customers to purchase and replace nearby, shorten the maintenance time and reduce the maintenance cost.

Fast, medium and slow three variable frequency filling, with adjustable speed, to ensure no dripping during filling. |

| 履带式压盖机

Crawler capping machine |

The squeezing mode is formed by crawler transportation, so that the bottle and the cover are squeezed and closed, and the function of pressing the bottle cap is achieved, so that the bottle body will not be squeezed and deformed, and it is stable, noiseless and free of air pressure.

The height can be flexibly adjusted according to the different heights of the target barrel. There is no need to disassemble the capping machine to adjust the height, but only the upper and lower heights can be adjusted by the top hand-operated mechanism.

After the height is adjusted, the capping machine is equipped with a locking device, and the capping machine height is locked after locking, so that the capping machine height will not be loosened due to long-term capping. |

Technical Specification

|

类别Category |

主要参数Main parameter (could be customized) |

| 设备规格Equipment specification | 12头全自动高精度中小包装灌装机12 Full-Automatic High-Precision Margarine Filling Machines |

| 灌装容量Filling capacity | 1L、3L、5L、20L |

| 生产能力Production capacity | 1800-2000瓶/小时(生产能力按1L计)1000-1300瓶/小时(生产能力按5L计)

500-650瓶/小时(生产能力按20L计) 1800-2000 bottles/hour (production capacity is calculated as 1L) 1000-1300 bottles/hour (production capacity is calculated as 5L) 500-650 bottles/hour (production capacity is calculated as 20L) |

| 灌装精度Filling precision | ≤0.2%(以3L计)≤ 0.2% (calculated by 3L) |

| 工作电源working power supply | 380V±10% 50HZ |

| 设备功率Equipment power | 12.45KW |

| 设备规格Equipment specification | L4540×W1750×H2370mm |

| 输送带长度Conveyor belt length | 15.14m |

| 工作面离地高度Height of working face from the ground | 650mm |

| 灌装主机重量Filling machine weight | 1.8T |

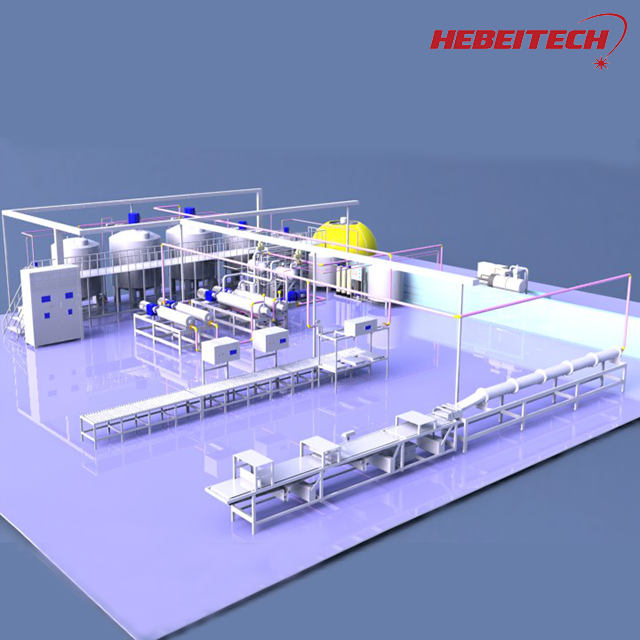

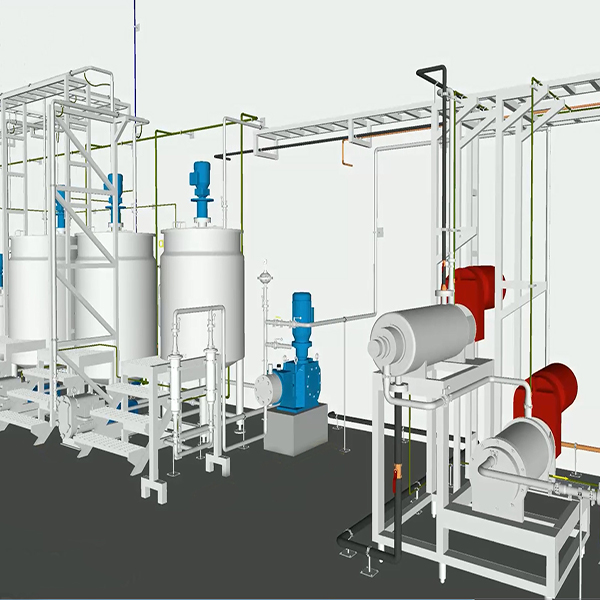

Site Commissioning

Product detail pictures:

Related Product Guide:

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for Fast delivery Pastry Production Line - Margarine Pail Filling Line China Manufacturer – Shipu , The product will supply to all over the world, such as: Salt Lake City, kazan, Saudi Arabia, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.