High reputation Shea Butter Filling Machine - Pasteurizer Model SPTP China Supplier – Shipu

High reputation Shea Butter Filling Machine - Pasteurizer Model SPTP China Supplier – Shipu Detail:

Equipment Description

Pasteurizer (Tube heat exchanger) is widely used for sterilization in the oil fat and milk processing industry, the material will be heated up to 75-90 degree, and kept for a short time, about 15-16 seconds, it can kill the pathogenic bacteria, while can keep most of the nutrition ingredient.

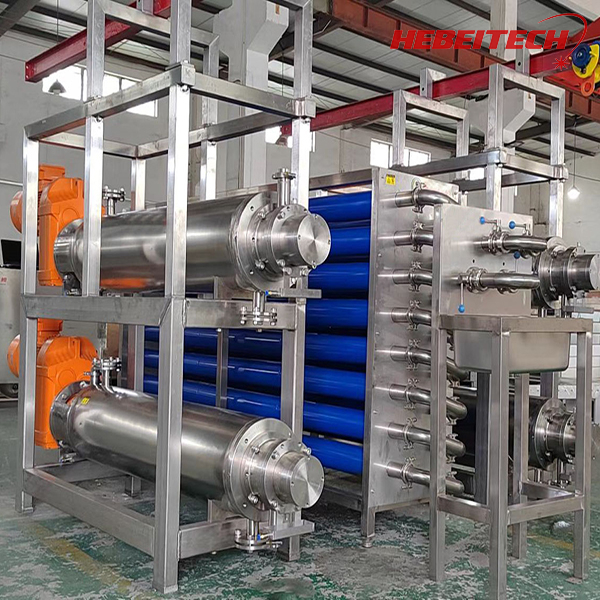

Equipment Picture

Equipment Details

Technical Specification

| 1、Working Condition | ||||||||||||||

| Capacity | 0.5-4t/h | Material Inlet | 50℃ | Steam Pressure | 0.6MPa | |||||||||

| 2、Design Requirement | ||||||||||||||

| Material Sterilization Temperature | 75℃ | Holding Time | 15S | Material Outlet Temperature | 60℃ | |||||||||

| 3、Main Technical Parameters | ||||||||||||||

| Item | Technical Parameter | Item | Technical Parameter | |||||||||||

| Model | SPTP-0.5/4T | Power | 5.5-10.5KW | |||||||||||

| Heat Exchange Area | 38M2 | Product Inlet/Outlet | φ38×1.5mm | |||||||||||

| Product Pipe Material, Diameter | SUS316L、¢12×1 | Cooling Water Inlet/Outlet | φ63×1.5mm | |||||||||||

| Outer Pipe Material, Diameter | SUS304、¢57×2 | Cooling Water Consumption | 9t/h | |||||||||||

| Automatic Control Of Sterilization Temperature | ±1℃ | Steam Pipe Diameter | φ50.8×3mm | |||||||||||

| Cleaning Type | Self CIP System | Steam Consumption | 150Kg/h | |||||||||||

| Compressor Air Consumption | 0.1M3/min | Compressor Air Pressure | 0.6Mpa | |||||||||||

| Weight | 1.6t | Dimensions | 4500×2000×2500 | |||||||||||

| 4、Configuration List | ||||||||||||||

| No | Item | Model Or Specification | Qty | Manufacturer | Remark | |||||||||

| 1 | Main body of tubular heat exchanger | SPTP-0.5/4T | 1 | Hebeitech | ||||||||||

| 2 | Brazed Heat Exchanger | 2M2 | 1 | Hebeitech | ||||||||||

| 3 | Balance Tank | 120L | 1 | Hebeitech | ||||||||||

| 4 | Hot Water Tank | 80L | 1 | Hebeitech | ||||||||||

| 5 | Centrifugal Pump | 10T/50M | 1 | Hebeitech | Power: 4KW | |||||||||

| 6 | Centrifugal Pump | 10T/50M | 1 | Hebeitech | Power: 4KW | |||||||||

| 7 | Hot Water Pump | CDL | 1 | CNP | Power: 2.2KW | |||||||||

| 8 | Steam Regulate Valve | DN32 | 1 | UK Spirax Sarco | ||||||||||

| 9 | Steam Pressure Reducer Valve | DN32 | 1 | UK Spirax Sarco | ||||||||||

| 10 | Steam Plunger Valve | DN32 | 1 | UK Spirax Sarco | ||||||||||

| 11 | Steam Filter | DN32 | 1 | UK Spirax Sarco | ||||||||||

| 12 | Steam Trap | DN25 | 1 | UK Spirax Sarco | ||||||||||

| 13 | Hot Water Back Pressure Valve | Pneumatic Back Pressure Valve | 1 | Hebeitech | ||||||||||

| 14 | Hot Water Switch Valve | Two Position Two Way Pneumatic Valve | 1 | Hebeitech | ||||||||||

| 15 | Constant Pressure Valve | ¢38 | 2 | AFLF/APV/GEA | ||||||||||

| 16 | Two Position Four Way Pneumatic Valve | ¢38 | 2 | AFLF/APV/GEA | ||||||||||

| 17 | Two Position Three Way Pneumatic Valve | ¢38 | 1 | AFLF/APV/GEA | ||||||||||

| 18 | Flow Meter | 0-10T/H | 1 | E+H | ||||||||||

| 19 | Acid And Alkali Diaphragm Pump | P0.29 | 2 | USA Wilden | ||||||||||

| 20 | Electrical Control Box | 304 | 1 | Hebeitech | ||||||||||

| 21 | Electrical Components | Match | 1 | France Schneider | ||||||||||

| 22 | Automatic Temperature Recorder | Match | 1 | Japan Yokogawa | Paperless Recorder | |||||||||

| 23 | Temperature Sensor | Pt100 | 3 | Germany Jumo | ||||||||||

| 24 | Concentrated Acid And Alkali Cylinder | 100L | 2 | Hebeitech | ||||||||||

| 25 | 10 “Color Touch Screen | Match | 1 | Siemens | ||||||||||

| 26 | PLC Program Controller | Match | 1 | Siemens | ||||||||||

| 27 | Frame | 304 | 1 | Hebeitech | ||||||||||

Site Commissioning

Product detail pictures:

Related Product Guide:

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for High reputation Shea Butter Filling Machine - Pasteurizer Model SPTP China Supplier – Shipu , The product will supply to all over the world, such as: Miami, Switzerland, Liberia, In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

Write your message here and send it to us