How to build a margarine factory?

Building a margarine factory requires careful planning and execution to ensure that the final product meets the required quality standards. Here are the steps to consider when building a margarine factory:

Conduct Market Research

The first step is to conduct thorough market research to determine the demand for margarine products in your target market. This will help you understand the potential size of your customer base, their preferences, and the competition.

Obtain Permits and Licenses

Building a margarine factory requires obtaining permits and licenses from relevant government agencies. You need to check the local regulations and guidelines for setting up a food processing factory in your area. This will include obtaining a business permit, a food processing license, and a health and safety certification.

Secure Funding

Setting up a margarine factory requires significant capital investment. You can secure funding from various sources, such as banks, investors, or government agencies that support small businesses.

Choose a Suitable Location

The location of the factory is critical to its success. Choose a location that is easily accessible for transportation of raw materials and finished products. Also, ensure that the area has a reliable supply of water and electricity.

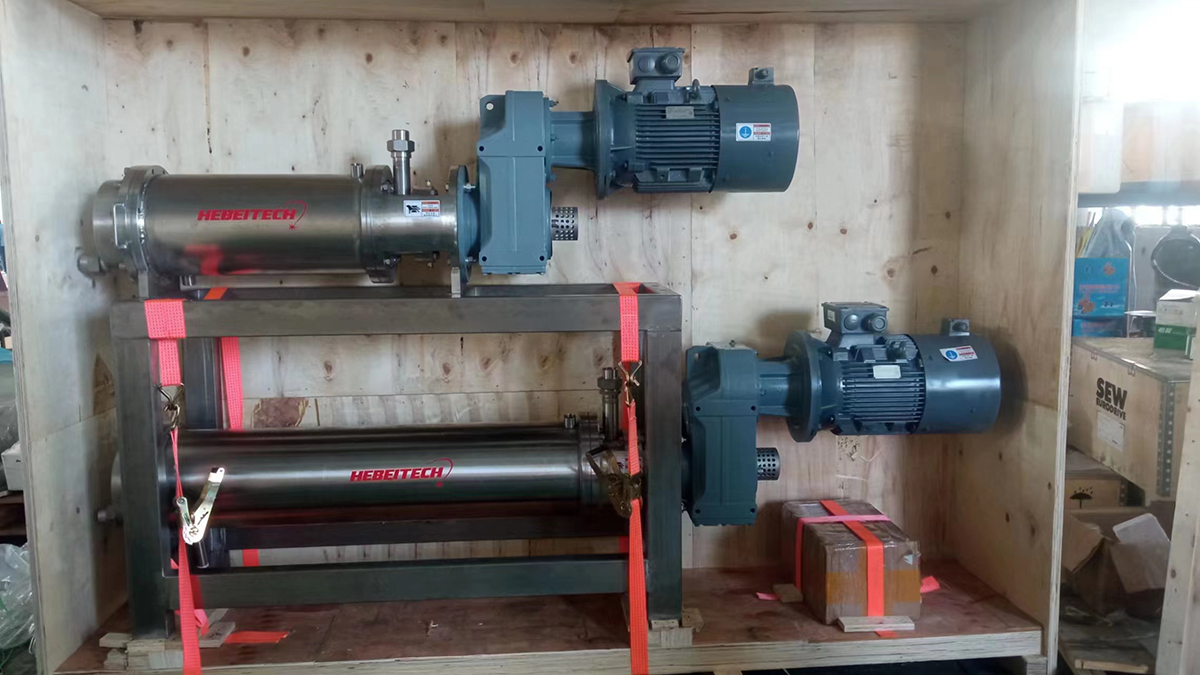

Acquire Equipment

Acquiring equipment is a critical step in building a margarine factory. You need to purchase specialized equipment, such as reactor, mixers, blenders, emulsifier, homogenizers, HP plunger pump, pasteurizer, votator, scraped surface heat exchanger, pin rotor machine, refrigerator unit and margarine packaging machines. Ensure that the equipment is of high quality, durable, and meets the required safety standards.

Hire Qualified Staff

Building a successful margarine factory requires a skilled and experienced team. Hire qualified staff, including production managers, quality control technicians, and sales and marketing personnel. Ensure that all staff members undergo the necessary training to ensure they understand their roles and responsibilities.

Source Raw Materials

Margarine is made from a combination of vegetable oils, water, salt, and emulsifiers. Source high-quality raw materials from reputable suppliers. Ensure that the raw materials meet the required quality standards.

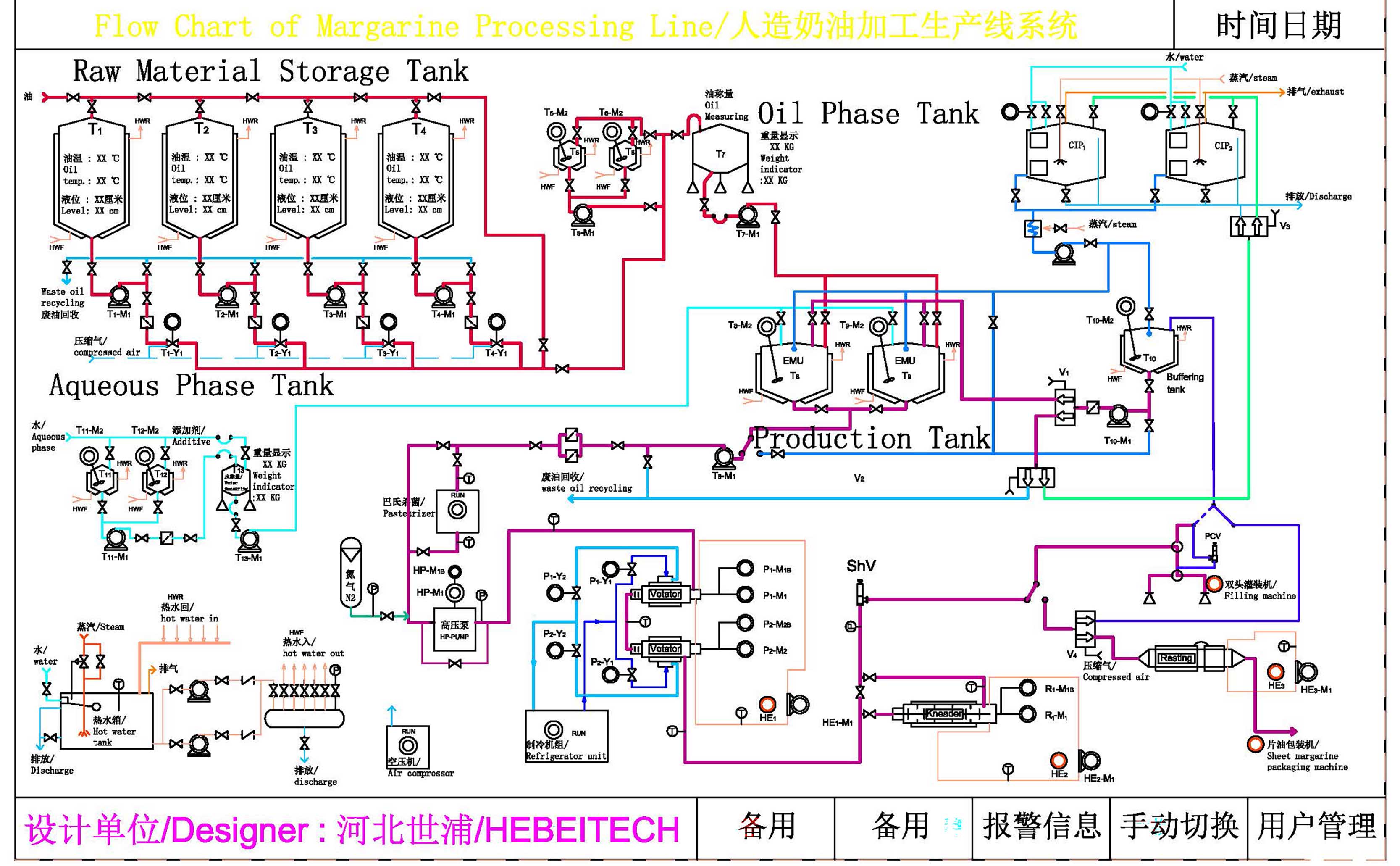

Develop a Production Process

Developing a production process is a critical step in building a margarine factory. You need to have a detailed process that outlines the various stages of production, from mixing the ingredients to packaging the final product.

Implement Quality

Control Procedures Implementing quality control procedures is critical to ensure that the final product meets the required quality standards. Establish strict quality control procedures for every stage of production to ensure that the final product is of high quality.

Marketing and Distribution

Develop a marketing strategy to promote your margarine products. This may include advertising, promotions, and social media marketing. Additionally, identify distribution channels that are appropriate for your target market.

In conclusion

Building a margarine factory requires careful planning and execution. Ensure that you conduct thorough market research, obtain the necessary permits and licenses, secure funding, choose a suitable location, acquire equipment (mainly emulsifier, scraped surface heat exchanger, votator, pin rotor machine and etc), hire qualified staff, source raw materials, develop a production process, implement quality control procedures, and develop a marketing and distribution strategy. With proper planning and execution, you can build a successful margarine factory that meets the needs of your target market.

Hebei shipu machinery technology co., ltd. Focus on the manufacturing, researching, technical consultant of margarine processing line, margarine machines, shortening production line, votator, scraped surface heat exchangers and etc.

Post time: Feb-28-2023