Margarine Production Technology

EXECUTIVE SUMMARY

Food companies today are like other manufacturing businesses not only focusing on the reliability and quality of the food processing equipment but also on various services which the supplier of the processing equipment can deliver. Apart from the efficient processing lines we deliver, we can be a partner from the initial idea or project stage to the final commissioning phase, not to forget the important after-market service.

Shiputec have more than 20 years’ experience for the food processing and packaging industry.

INTRODUCTION TO OUR TECHNOLOGY

VISION AND COMMITMENT

Shiputec segment designs, manufactures and markets process engineering and automation solutions to the dairy, food, beverage, marine, pharmaceutical and personal care industries through its global operations.

We are committed to helping our customers all over the world to improve the performance and profitability of their manufacturing plant and processes. We achieve this by offering a wide range of products and solutions from engineered components to design of complete process plants supported by world-leading applications and development expertise.

We continue to help our customers optimize the performance and profitability of their plant throughout its service life with support services tailored to their individual needs through a coordinated customer service and spare parts network.

CUSTOMER FOCUS

Shiputec develops, manufactures and installs modern, high efficient and reliable processing lines for the food industry. For the production of crystallized fat products like margarine, butter, spreads and shortenings Shiputec offers solutions which also comprise process lines for emulsified food products such as mayonnaise, sauces and dressings.

MARGARINE PRODUCTION

Margarine and related products contain a water phase and a fat phase and can thus be characterized as water-in-oil (W/O) emulsions in which the water phase is finely dispersed as droplets in the continuous fat phase. Depending on the application of the product, the composition of the fat phase and the manufacturing process are chosen accordingly.

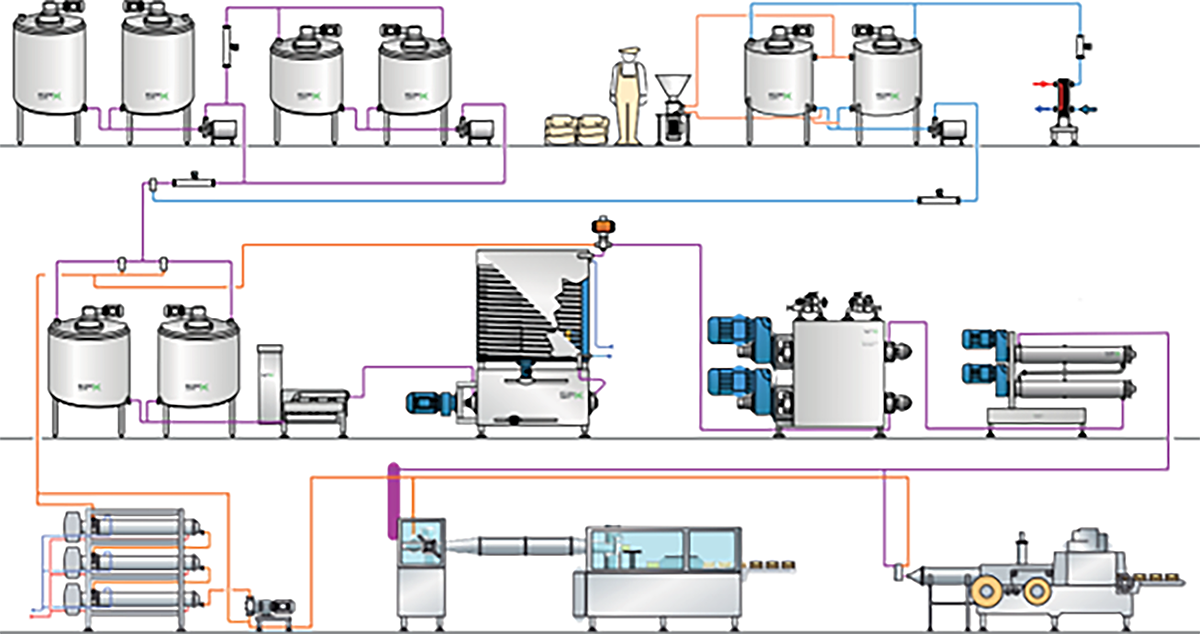

Apart from the crystallization equipment, a modern manufacturing facility for margarine and related products will typically include various tanks for oil storage as well as for emulsifier, water phase and emulsion preparation; the size and number of tanks are calculated based on capacity of the plant and product portfolio. The facility also includes a pasteurization unit and a remelting facility. Thus, the manufacturing process can in general be divided into the following sub-processes (please see diagram 1):

PREPARATION OF TH E WATER PHASE AND THE FAT PHASE (ZONE 1 )

The water phase is often prepared batch-wise in the water phase tank. The water should be of good drinking quality. If drinking quality water cannot be guaranteed, the water can be subjected to pre-treatment by means of e.g. a UV or filter system.

Apart from the water, the water phase can consist of salt or brine, milk proteins (table margarine and low fat spreads), sugar (puff pastry), stabilizers (reduced and low fat spreads), preservatives and water-soluble flavors.

The major ingredients in the fat phase, the fat blend, normally consist of a blend of different fats and oils. In order to achieve margarine with the desired characteristics and functionalities, the ratio of fats and oils in the fat blend is decisive for the performance of the final product.

The various fats and oils, either as fat blend or single oils, are stored in oil storage tanks typically placed outside the production facility. These are kept at stable storage temperature above the melting point of the fat and under agitation in order to avoid fractionation of the fat and to allow easy handling.

Apart from the fat blend, the fat phase typically consists of minor fat-soluble ingredients such as emulsifier, lecithin, flavor, color and antioxidants. These minor ingredients are dissolved in the fat blend before the water phase is added, thus before the emulsification process.

EMULSION PREPARATION ( ZONE 2 )

The emulsion is prepared by transferring various oils and fat or fat blends to the emulsion tank. Usually, the high melting fats or fat blends are added first followed by the lower melting fats and the liquid oil. To complete the preparation of the fat phase, the emulsifier and other oil-soluble minor ingredients are added to the fat blend. When all the ingredients for the fat phase have been properly mixed, the water phase is added and the emulsion is created under intensive but controlled mixing.

Different systems can be used for metering the various ingredients for the emulsion of which two are working batch- wise:

Flow meter system

Weighing tank system

A continuous in-line emulsification system is a less preferred but used solution in e.g. high capacity lines where limited space for emulsion tanks is available. This system is using dosing pumps and mass flow meters to control the ratio of the added phases into a small emulsion tank.

The above-mentioned systems can all be controlled fully automatically. Some older plants, however, still have manually controlled emulsion preparation systems but these are labor- demanding and not recommended to install today due to the strict traceability rules.

The flow meter system is based on batch-wise emulsion preparation in which the various phases and ingredients are measured by mass flow meters when transferred from the various phase preparation tanks into the emulsion tank. The accuracy of this system is +/-0.3%. This system is characterized by its insensibility to outside influences like vibrations and dirt.

The weighing tank system is like the flow meter system based on batch-wise emulsion preparation. Here the amounts of ingredients and phases are added directly to the emulsion tank which is mounted on load cells controlling the amounts added to the tank.

Typically, a two-tank system is used for preparing the emulsion in order to be able to run the crystallization line continuously. Each tank works as a preparation and buffer tank (emulsion tank), thus the crystallization line will be fed from one tank while a new batch will be prepared in the other and vice versa. This is called the flip-flop system.

A solution where the emulsion is prepared in one tank and when ready is transferred to a buffer tank from where the crystallization line is fed is also an option. This system is called the premix/buffer system.

PASTEURIZATION ( ZONE 3 )

From the buffer tank the emulsion is normally continuously pumped through either a plate heat exchanger (PHE) or a low pressure scraped surface heat exchanger (SSHE), or high pressure SSHE for pasteurization prior to entering the crystallization line.

For full fat products a PHE is typically used. For lower fat versions where the emulsion is expected to exhibit a relatively high viscosity and for heat-sensible emulsions (e.g. emulsions with high protein content) the SPX system as a low pressure solution or the SPX-PLUS as a high pressure solution is recommended.

The pasteurization process has several advantages. It ensures inhibition of bacterial growth and growth of other micro-organisms, thus improving the microbiological stability of the emulsion. Pasteurization of the water phase only is a possibility, but pasteurization of the complete emulsion is preferred since the pasteurization process of the emulsion will mini-mise the residence time from pasteurized product to filling or packing of final product. Also, the product is treated in an in-line process from pasteurization to filling or packing of the final product and pasteurization of any rework material is ensured when the complete emulsion is pasteurized.

In addition, pasteurization of the complete emulsion ensures that the emulsion is fed to the crystallization line at a constant temperature achieving constant processing parameters, product temperatures and product texture. In addition, occurrence of pre-crystallized emulsion fed to the crystallization equipment is prevented when the emulsion is properly pasteurized and fed to the high pressure pump at a temperature 5-10°C higher than the melting point of the fat phase.

A typical pasteurization process will after preparation of the emulsion at 45-55°C include a heating and holding sequence of the emulsion at 75-85°C for 16 sec. and subsequently a cooling process to a temperature of 45-55°C. The end temperature depends on the melting point of the fat phase: the higher the melting point, the higher the temperature.

CHILLING, CRYSTALLIZATION AND KNEADING (ZONE 4 )

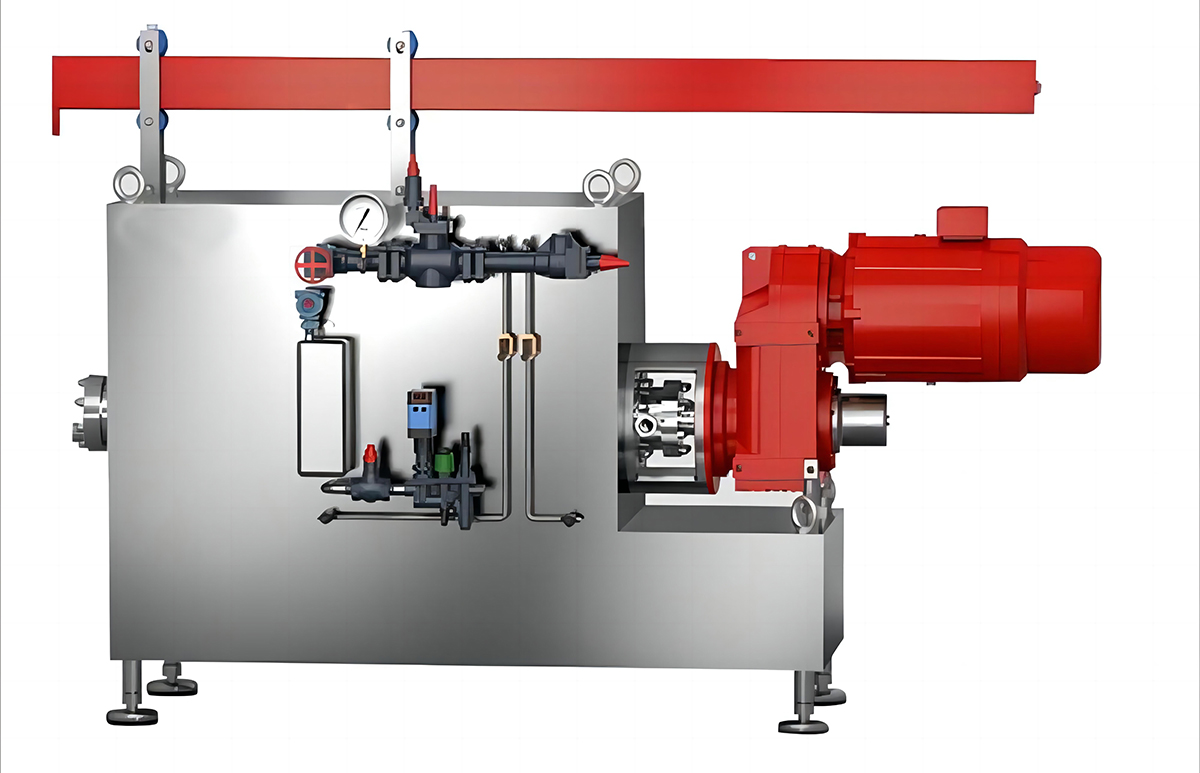

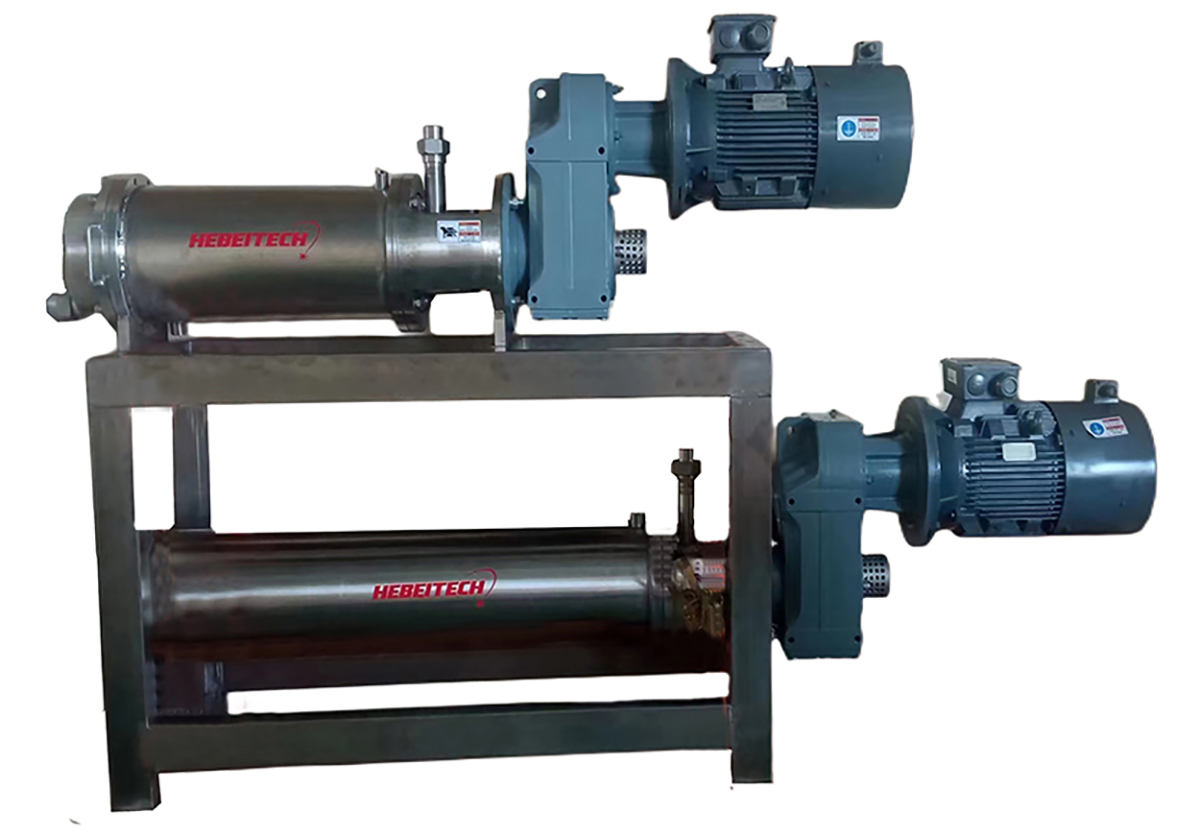

The emulsion is pumped to the crystallization line by means of a high pressure piston pump (HPP). The crystallization line for the production of margarine and related products typically consists of a high pressure SSHE which is cooled by ammonia or Freon type cooling media. Pin rotor machine(s) and/or intermediate crystallizers are often included in the line in order to add extra kneading intensity and time for the production of plastic products. A resting tube is the final step of the crystallization line and is only included if the product is packed.

The heart of the crystallization line is the high pressure SSHE, which the warm emulsion is super-cooled and crystallized on the inner surface of the chilling tube. The emulsion is efficiently scraped off by the rotating scrapers, thus the emulsion is chilled and kneaded simultaneously. When the fat in the emulsion crystallizes, the fat crystals form a three-dimensional network entrapping the water droplets and the liquid oil, resulting in products with properties of plastic semi-solid nature.

Depending on the type of product to be manufactured and the type of fats used for the particular product, the configuration of the crystallization line (i.e. the order of the chilling tubes and the pin rotor machines) can be adjusted to provide the optimum configuration for the particular product.

Since the crystallization line usually manufactures more than one specific fat product, the SSHE often consists of two or more cooling sections or chilling tubes in order to meet the requirements for a flexible crystallization line. When producing different crystallized fat products of various fat blends, flexibility is needed since the crystallization characteristics of the blends might differ from one blend to another.

The crystallization process, the processing conditions and the processing parameters have a great influence on the characteristics of the final margarine and spread products. When designing a crystallization line, it is important to identify the characteristics of the products planned to be manufactured on the line. To secure the investment for the future, flexibility of the line as well as individually controllable processing parameters are necessary, since the range of products of interest might change with time as well as raw materials.

The capacity of the line is determined by the cooling surface available of the SSHE. Different size machines are available ranging from low to high capacity lines. Also various degrees of flexibility are available from single tube equipment to multiple tube lines, thus highly flexible processing lines.

After the product is chilled in the SSHE, it enters the pin rotor machine and/or intermediate crystallizers in which it is kneaded for a certain period of time and with a certain intensity in order to assist the promotion of the three-dimensional network, which on the macroscopic level is the plastic structure. If the product is meant to be distributed as a wrapped product, it will enter the SSHE again before it settles in the resting tube prior to wrapping. If the product is filled into cups, no resting tube is included in the crystallization line.

PACKING, FILLING AND REMELTING ( ZONE 5 )

Various packing and filling machines are available on the market and will not be described in this article. However, the consistency of the product is very different if it is produced to be packed or filled. It is obvious that a packed product must exhibit a firmer texture than a filled product and if this texture is not optimal the product will be diverted to the remelting system, melted and added to the buffer tank for re-processing. Different remelting systems are available but the most used systems are PHE or low pressure SSHE.

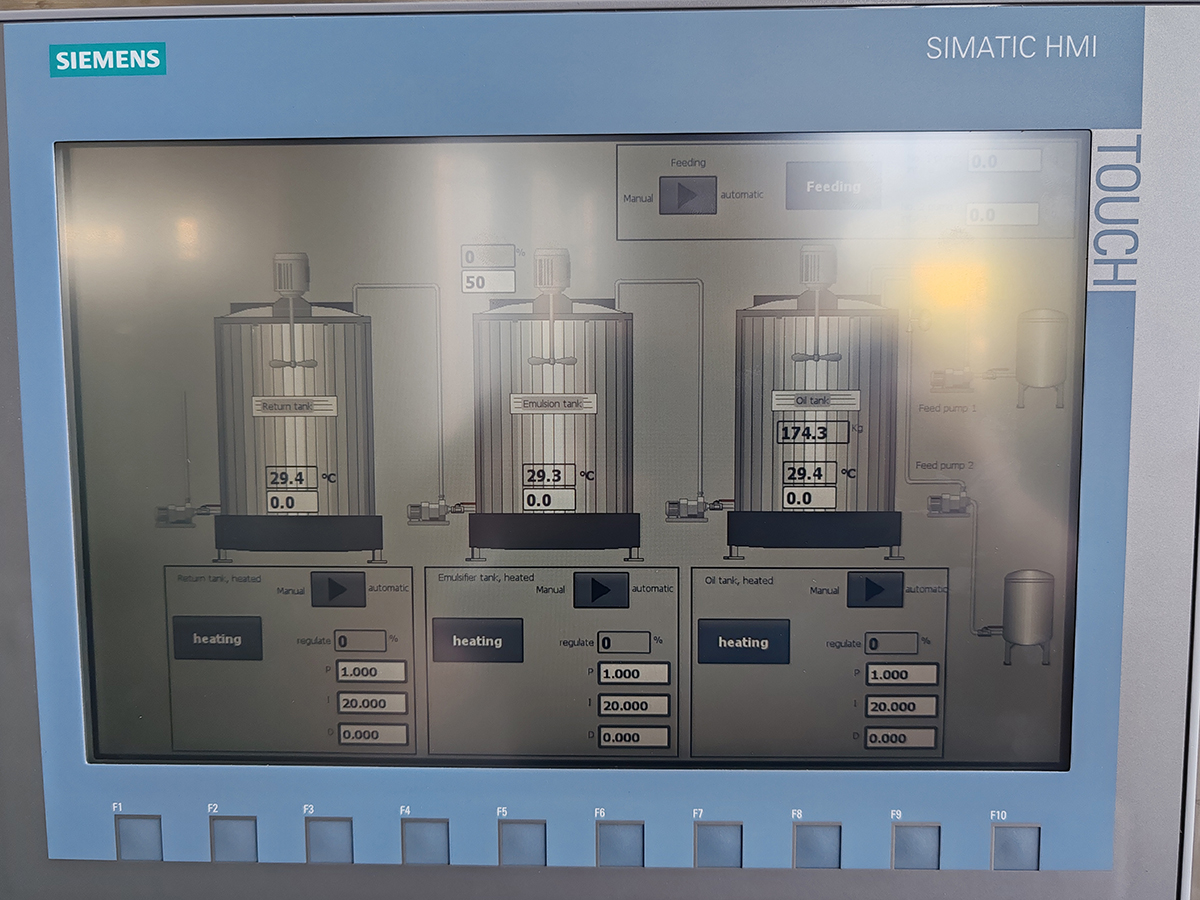

AUTOMATION

Margarine, like other food products, is in many factories today produced under strict traceability procedures. These procedures typically covering the ingredients, the production and the final product result not only in an enhanced food safety but also in a constant food quality. Traceability demands can be implemented in the control system of the factory and Shiputec control system is designed to control, record and document important conditions and parameters concerning the complete manufacturing process.

The control system is equipped with password protection and features historic data logging of all parameters involved in the margarine processing line from recipe information to final product evaluation. The data logging includes the capacity and output of the high pressure pump (l/hour and back pressure), product temperatures (incl. pasteurization process) during crystallization, cooling temperatures (or cooling media pressures) of the SSHE, speed of the SSHE and the pin rotor machines as well as load of motors running the high pressure pump, the SSHE and the pin rotor machines.

Control system

During processing, alarms will be sent to the operator if the processing parameters for the specific product are out of limits; these are set in the recipe editor prior to production. These alarms have to be acknowledged manually and actions according to procedures have to be taken. All alarms are stored in a historic alarm system for later view. When the product leaves the production line in a suitably packed or filled form, it is apart from the product name typically marked with a date, time and batch identification number for later tracking. The complete history of all the production steps involved in the manufacturing process is thus filed for the security of the producer and the end user, the consumer.

CIP

CIP cleaning plants (CIP = cleaning in place) are also part of a modern margarine facility since margarine production plants should be cleaned on a regular basis. For traditional margarine products once a week is a normal cleaning interval. However, for sensitive products like low fat (high water content) and/or high protein containing products, shorter intervals between the CIP are recommended.

In principle, two CIP systems are used: CIP plants which use the cleaning media only once or the recommended CIP plants which operate via a buffer solution of the cleaning media where media such as lye, acid and/or disinfectants are returned to the individual CIP storage tanks after use. The latter process is preferred since it represents an environmentally-friendly solution and it is an economical solution in regard to consumption of cleaning agents and hereby the cost of these.

In case several production lines are installed in one factory, it is possible to set up parallel cleaning tracks or CIP satellite systems. This results in a significant reduction in cleaning time and energy consumption. The parameters of the CIP process are automatically controlled and logged for later trace in the control system.

FINAL REMARKS

When producing margarine and related products, it is important to keep in mind that it is not only the ingredients like the oils and fats used or the recipe of the product which determine the quality of the final product but also the configuration of the plant, the processing parameters and the state of the plant. If the line or the equipment is not well maintained, there is a risk that the line is not efficiently performing. Therefore, to produce high quality products, a well functioning plant is a must but the choice of fat blend with characteristics which correspond to the final application of the product is also important as well as a correct configuration and choice of processing parameters of the plant. Last but not least the final product has to be temperature-treated according to final use.

Post time: Dec-19-2023