Abstract

Pastry margarine must be plastic and steady. The technics flow of producing pastry margarine can be arranged very easy by tubularchiller (tubular scraped surface heat exchanger). During the deep-processing of oil, cooling has significant influence on the crystallization of pastry margarine. Different margarine needs different process and tempering condition.

Pastry margarine must be plastic and steady. The technics flow of producing pastry margarine can be arranged very easy by tubularchiller (tubular scraped surface heat exchanger). During the deep-processing of oil, cooling has significant influence on the crystallization of pastry margarine. Different margarine needs different process and tempering condition.

Key words : pastry margarine; chilling drum; tubular chiller, scraped surface heat exchanger, margarine production.

Technical introduction of tubular chiller

Although flaky margarine products have been in production for many years, people have been trying to figure out the best way for process conditions, mainly on the crystallization of different product formula under different processing conditions. Before the invention of the scraper heat exchanger, or tube quenching machine, all margarine products were produced using drum quenching and kneading machines. Because of the tube quenching processing machine has many advantages compared with other processing machines, so now the margarine manufacturers are using its production of flaky pastry margarine, this paper on the quenching tube processing machine to produce flaky pastry margarine process to do some introduction.

The main properties of flaky margarine are its plasticity and stability. When the margarine is folded and rolled out repeatedly, the layers must remain unbroken in the dough, so plasticity is important; Stability is also important. If the margarine is not firm enough to become soft or oil permeable, and is absorbed into the dough, the oil layer between the dough layers will be greatly reduced.

The structure of rotary drum quench machine is relatively simple, only need to adjust a few parameters in production can produce the crisp margarine products. The flaky pastry margarine produced by the drum quench machine has good plasticity, is not easy to penetrate oil, and is very stable in a large temperature range. Tube quenching machine than drum quenching machine in performance has made greater progress, which is mainly reflected in:

(1)In the sealed pipe processing products, good sealing, sanitary conditions will also improve a lot;

(2)The realization of high pressure operation, which is particularly important for the production of crisp margarine;

(3)Good flexibility, can flexibly change speed, pressure, freezing strength and other processing conditions.

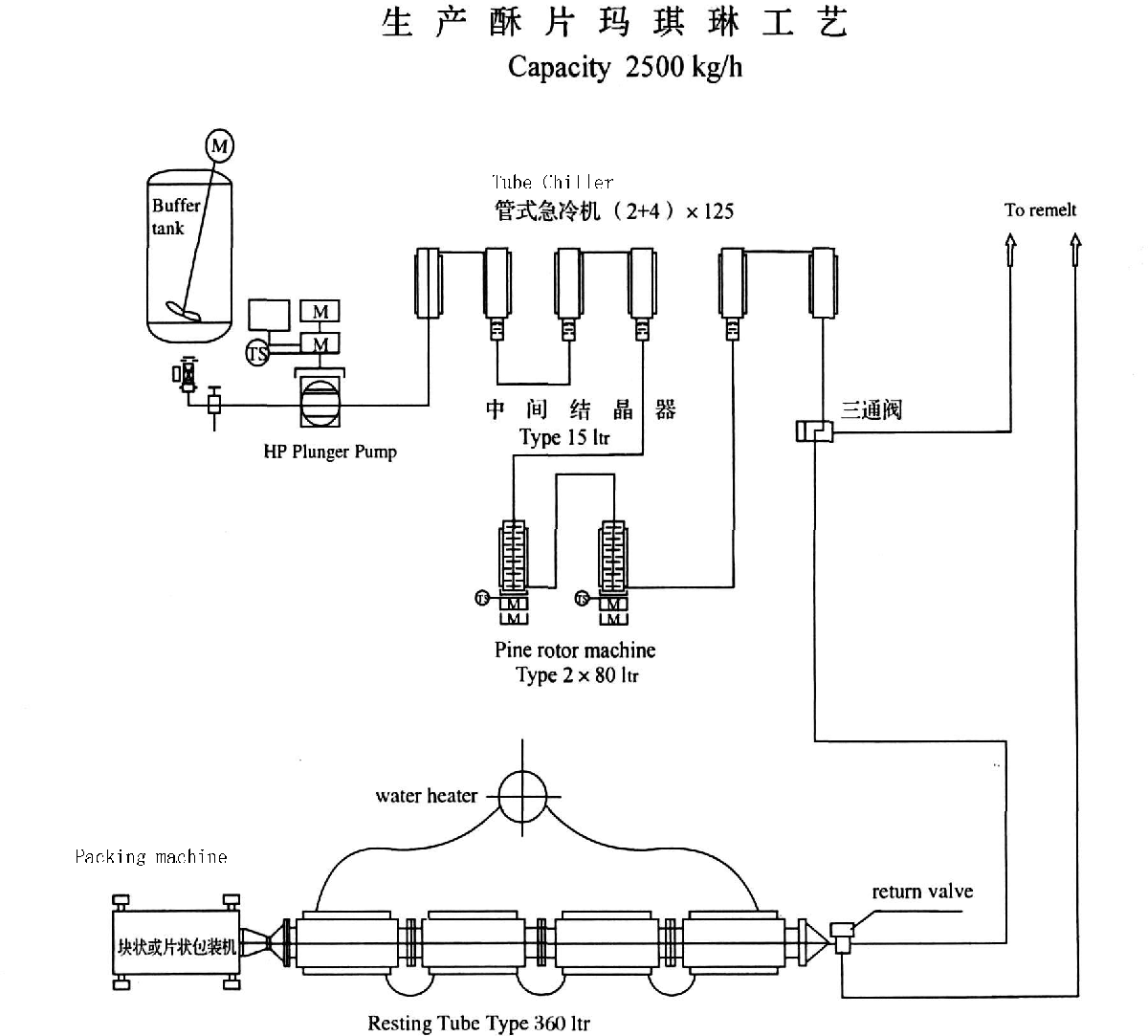

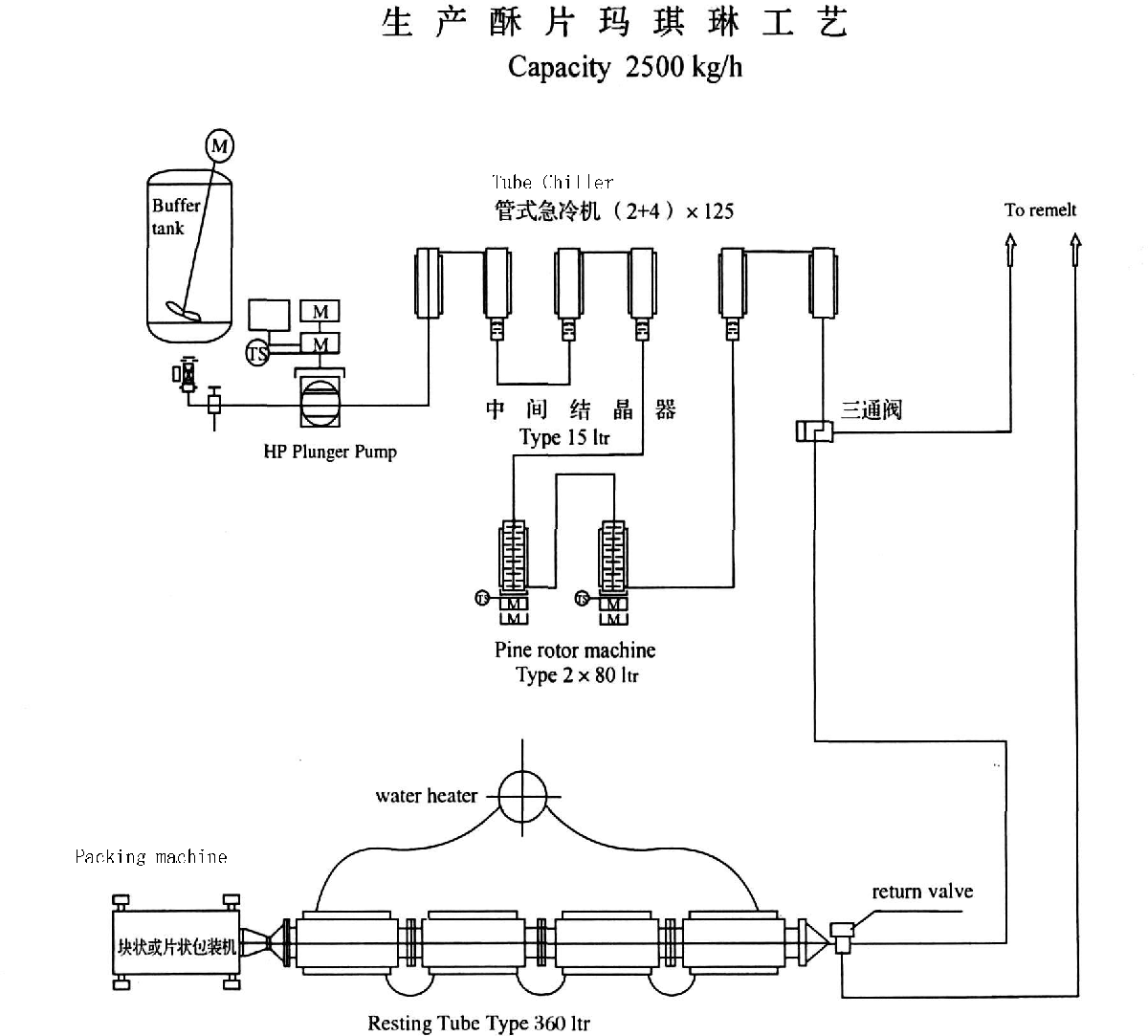

The representative process for the production of flaky pastry margarine by tube quenching machine is as follows:

High pressure plunger pump ※ High pressure tubular scraped surface heat exchanger (Unit A) ※ Intermediate crystallizer set ※ Stirring pine rotor machine (Unit B)※ Large capacity rest tube ※ Slice/block packing.

The function of the intermediate crystallizer is equivalent to that of the stirring kneader. It is located on the quench pipe of the processing machine and driven to rotate by the cutter shaft of the processing machine.

It is convenient to adjust the processing flow of the product to produce flaky pastry margarine with tube quenching machine. The purpose of adjusting the process can be achieved by changing the connection mode of the connecting pipe between quenching pipe group (unit A) and kneading unit (unit B), which is easier to operate. For example, the stirring kneading unit (unit B) can be placed in the middle of the quench pipe of unit A, following the flow of A 1 ※A 2 ※B1 ※B2 ※A 3 ※A 4, or changing to the flow of A 1 ※A 2 ※A 3 ※A 4 ※B1 ※B2. By simply changing the processing process can improve product quality. In the above process, the process of placing unit B in the middle of the quench tube of unit A is particularly suitable for the vegetable oil formulation based on palm oil, which has been proved many times in production practice. And when the main material of the product is cattle, better results can be obtained by placing unit B after unit A.

The kneading capacity is determined by the formulation of the product, for example, a relatively large kneading capacity should be used for the oil formulation with slow crystallization. In rapid cooling pipe production process, the kneading effect is the capacity of the intermediate group and the capacity of the crystallizer and whip the kneading unit (B) the sum of the capacity of the unit, so when a change in the product formula, need to adjust capacity of kneading process, either through B unit capacity increase or decrease, can increase or decrease in the middle mold capacity, It can even be done by adding and subtracting at the same time, very flexible.

The kneading capacity is determined by the formulation of the product, for example, a relatively large kneading capacity should be used for the oil formulation with slow crystallization. In rapid cooling pipe production process, the kneading effect is the capacity of the intermediate group and the capacity of the crystallizer and whip the kneading unit (B) the sum of the capacity of the unit, so when a change in the product formula, need to adjust capacity of kneading process, either through B unit capacity increase or decrease, can increase or decrease in the middle mold capacity, It can even be done by adding and subtracting at the same time, very flexible.

Post time: Dec-30-2021