Process of Margarine

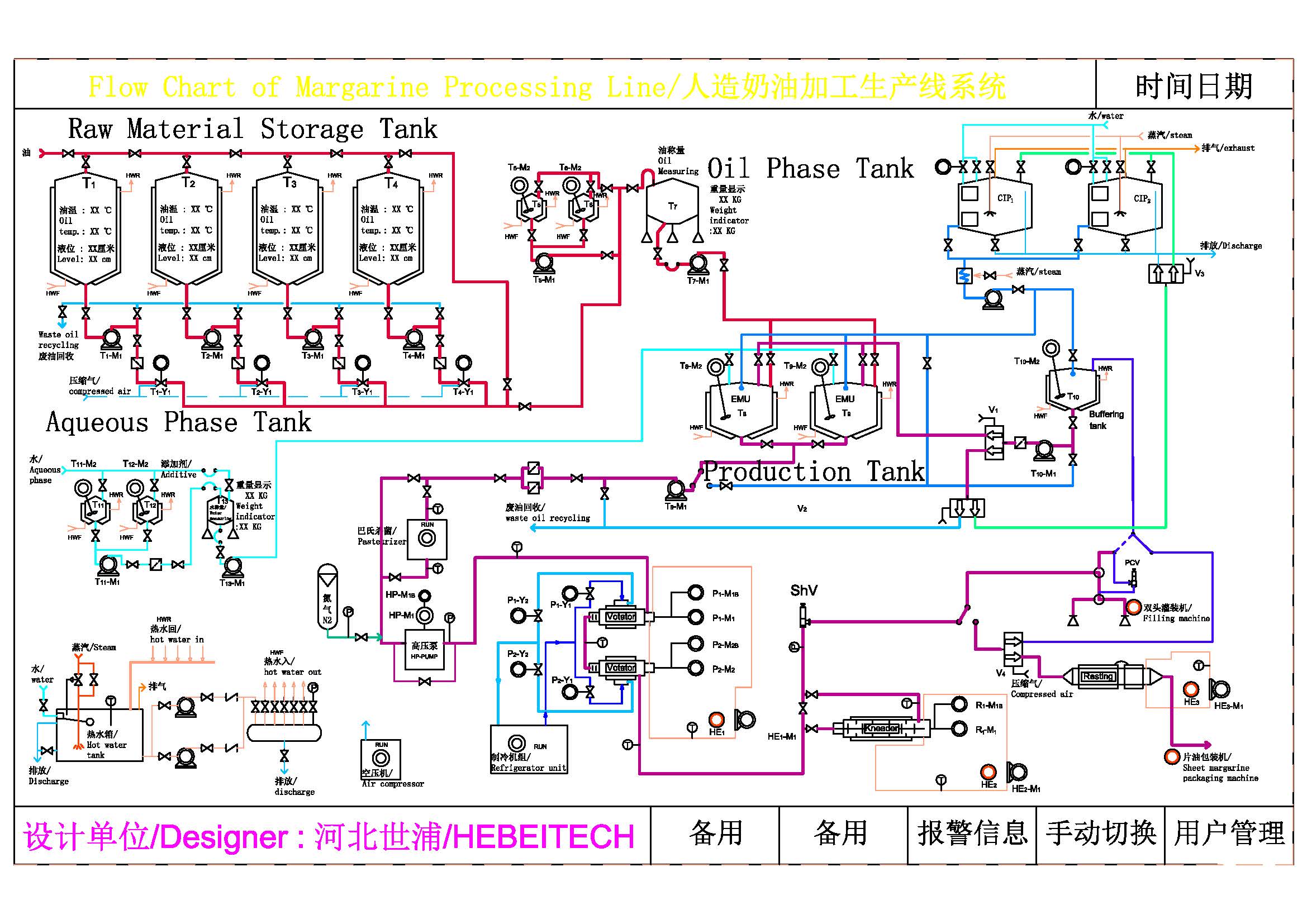

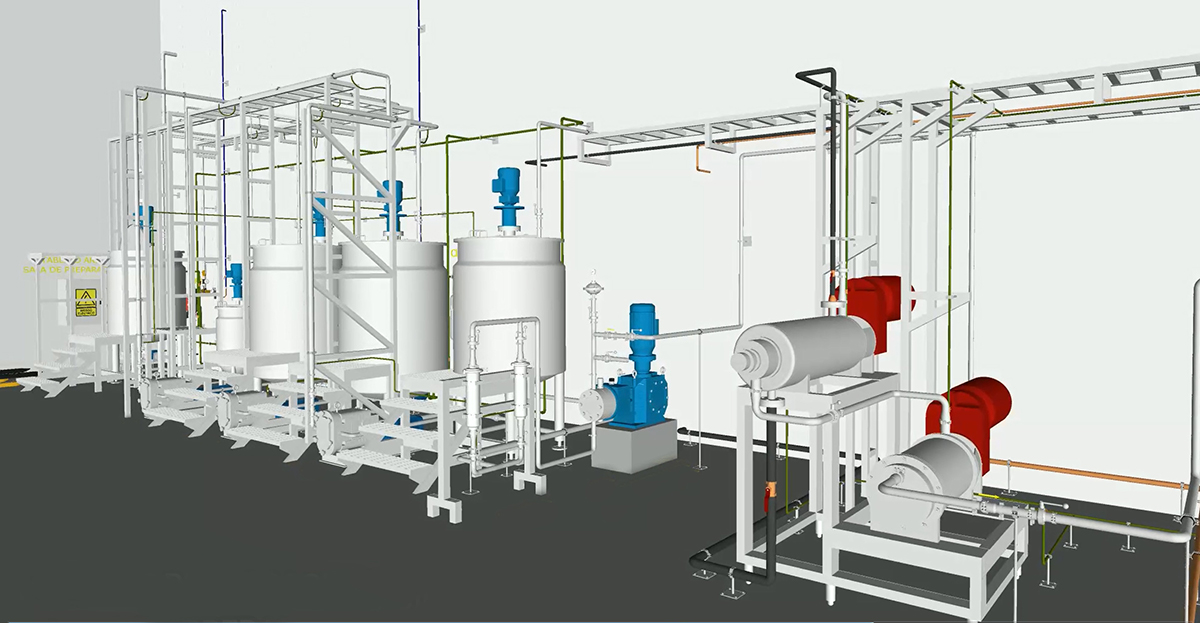

The production process of margarine involves several steps to create a spreadable and shelf-stable product that resembles butter but is typically made from vegetable oils or a combination of vegetable oils and animal fats. The main machine includes emulsification tank, votator, scraped surface heat exchanger, pin rotor machine, high pressure pump, pasteurizer, resting tube, packaging machine and etc.

Here is an overview of the typical process of margarine production:

Oil Blending (mixing tank): Different types of vegetable oils (such as palm, soybean, canola, or sunflower oil) are blended together to achieve the desired fat composition. The choice of oils affects the final texture, taste, and nutritional profile of the margarine.

Hydrogenation: In this step, unsaturated fats in the oils are partially or fully hydrogenated to convert them into more solid saturated fats. Hydrogenation increases the melting point of the oils and improves the stability of the final product. This process can also result in the formation of trans fats, which may be reduced or eliminated through more modern processing techniques.

Emulsification (emulsification tank): The blended and hydrogenated oils are mixed with water, emulsifiers, and other additives. Emulsifiers help stabilize the mixture by preventing oil and water from separating. Common emulsifiers include lecithin, mono- and diglycerides, and polysorbates.

Pasteurization (pasteurizer): The emulsion is heated to a specific temperature to pasteurize it, killing any harmful bacteria and extending the shelf life of the product.

Cooling and Crystallization (votator or scraped surface heat exchager): The pasteurized emulsion is cooled and allowed to crystallize. This step influences the texture and consistency of the margarine. Controlled cooling and crystallization help create a smooth and spreadable final product.

Adding Flavor and Color: Natural or artificial flavors, colors, and salt are added to the cooled emulsion to enhance the taste and appearance of the margarine.

Packaging: The margarine is pumped into containers such as tubs or sticks, depending on the intended consumer packaging. The containers are sealed to prevent contamination and maintain freshness.

Quality Control: Throughout the production process, quality control checks are performed to ensure the margarine meets the desired taste, texture, and safety standards. This includes testing for consistency, flavor, color, and microbiological safety.

Modern margarine production processes often focus on minimizing the use of hydrogenation and reducing trans fat content. Manufacturers may use alternative processes, such as interesterification, which rearranges the fatty acids in the oils to achieve desired properties without forming trans fats.

It's important to note that the specific process can vary between manufacturers and regions, and newer developments in food technology continue to influence the way margarine is produced. Additionally, the demand for healthier and more sustainable products has led to the development of margarines with reduced saturated and trans fats, as well as those made from plant-based ingredients.

Post time: Aug-21-2023