What is the advantage of scraped surface heat exchanger?

For large installations where vacuum crystallization may seem attractive, scraper crystallizers are cost effective. The design minimizes shear stress on fine crystals, but is robust enough to handle hard crystals.

What is scraped surface heat exchanger or votator?

Used to heat or cool products that other types of heat exchangers cannot handle continuously. Products for this application: heat sensitive, film forming, high viscosity, particle size or fineness that other heat exchangers cannot accommodate.

How does scraped surface heat exchanger or votator work?

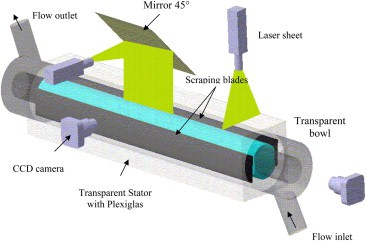

In scratch heat exchangers, spring-loaded rotating blades scrape the surface and effectively remove liquid from the surface. Alternatively, the blades move against the heat transfer surface under the influence of rotational forces.

What is the process of scraped surface heat exchanger?

The “Votator process” for making such products allows the rapid cooling of molten fat in a Votator face-scraped surface heat exchanger, resulting in the formation of many tiny crystals. Nitrogen can be injected with molten fat, stirred under pressure and in a closed system.

Why choose our scraped surface heat exchanger?

On base of 20 year’s experience, scraped surface heat exchangers have been replacing slow, inefficient batching operations with more uniform, controlled, and repeatable continuous processing.

Hebei Shipu Machinery can provide full set of custard cream making machine, margarine pilot plant, shortening machine, margarine machine and vegetable ghee machine.

Post time: Sep-24-2022