Renewable Design for Ketchup Pasteurization And Cooling System – Puff Margarine/ Table Margarine Production Line China Manufacturer – Shipu

Renewable Design for Ketchup Pasteurization And Cooling System – Puff Margarine/ Table Margarine Production Line China Manufacturer – Shipu Detail:

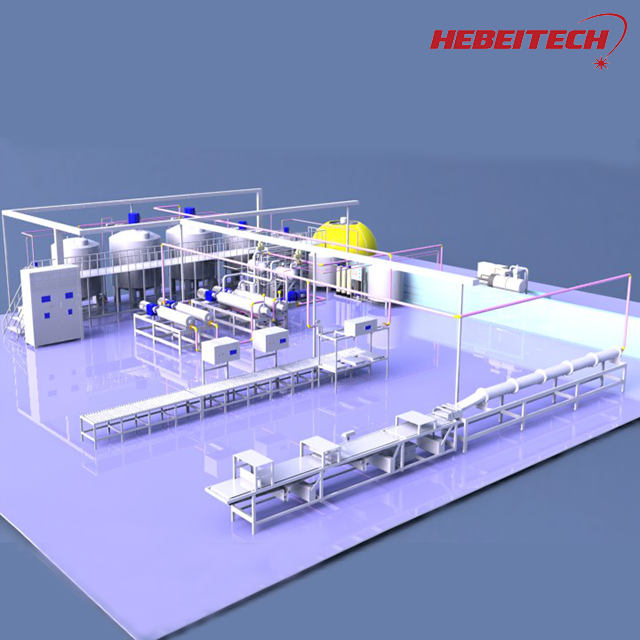

General Sketch Map

Puff pastry margarine or table margarine is very popular in the bakery industry,the raw material include palm oil, vegetable oils, animal fat, partially hydrogenated oils and fats, marine oils, palm kernel oil, lard, beef tallow, palm stearin, coconut oil, milk powder, salt and etc.

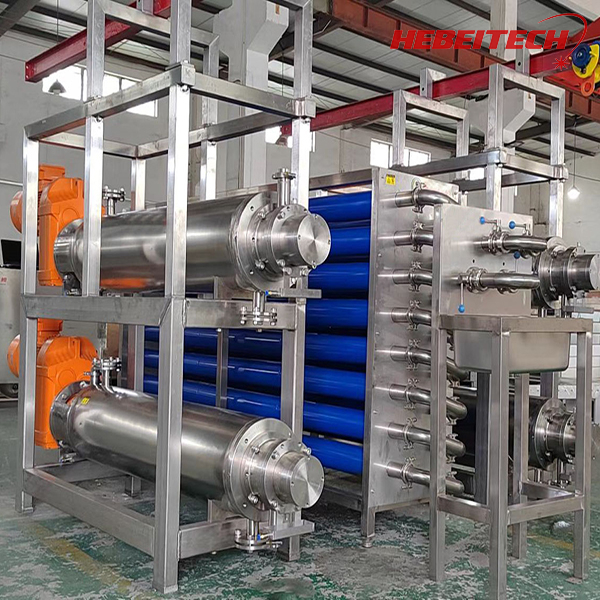

Scraped Surface Heat Exchanger (Unit A)

Is modeled on the Votator type of scrap surface heat exchanger to complete the oil crystallization by chiller system. It combines the special features of the European design, and shares many small interchangeable components, like mechanical seal, scraper blades and etc.

Pin Rotor Machine (Unit C)

Consists of a hot water jacketed cylinder with a row of fixed static pins (optional 3 rows) and a concentric shaft carrying pins in a helical or straight pattern. The rotating shaft pins intermesh with the static pins to provide the necessary kneading function for softening the shortening. The very high operating pressure mechanical seal is the same as SSHE for standardization.

Resting Tube (Unit B)

Consists of multi-sections of jacketed cylinders to provide the desired retention time for proper crystal growth. Internal orifice plates are provided to extrude and worked the product to modify the crystal structure to give the desired physical properties. The outlet design is a transition piece to accept a customer specific extruder, The custom extruder is required to produce sheet puff pastry or block margarine and is adjustable for thickness.

Pasteurizer

Pasteurizer is widely used in the oil fat and milk processing industry, the material will be heated up to 75-90 degree, and kept for a short time, about 15-16 seconds, it can kill the pathogenic bacteria, while can keep most of the nutrition ingredient.

Utility Equipment

Including Oil storage tank, Blending tank, Emulsification tank, High pressure pump, Bitzer chiller, Cooling tower, Water treatment unit, Air compressor, Boiler and etc.

Packaging Equipment

Depending on the market demand, we can supply various of packaging machine, like Carton filling & packaging machine, Puff pastry packaging machine, Sachet filling & packaging machine, Tin can filling & packaging machine, Cup filling & packaging, or we can design according to customer’s requirements.

Site Commissioning

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for Renewable Design for Ketchup Pasteurization And Cooling System – Puff Margarine/ Table Margarine Production Line China Manufacturer – Shipu , The product will supply to all over the world, such as: Algeria, Irish, Hanover, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.