Scraped Surface Heat Exchanger China Factory Model SPA-1000/2000

Scraped Surface Heat Exchanger

Our chilling unit (A unit) is modeled after the Votator type of scrap surface heat exchanger and combines the special features of the European design to take advantage of the two worlds. It shares many small interchangeable components. Mechanical seal and scraper blades are typical interchangeable parts. The heat transfer cylinder consists of a pipe in pipe design with inner pipe for product and outer pipe for cooling refrigerant. The inner tube is designed for very high pressure process operation. The jacket is designed for flooded direct evaporative cooling of either Freon or ammonia.

SPA SSHE Advantage

*Outstanding Durability

Completely sealed, fully insulated, corrosion-free stainless steel casing guarantees years of trouble-free operation.

*Narrower Annular Space

The narrower 7mm annular space is specially designed for the crystallization of grease to ensure more efficient cooling.*Higher Shaft Rotation Speed

Shaft rotation speed up to 660rpm brings better quenching and shearing effect.

*Improved Heat Transmission

Special, corrugated chilling tubes improve the heat transmission value.

*Easy Cleaning and Maintenance

In terms of cleaning, Hebeitech aims to make the CIP cycle fast and efficient. In terms of maintenance, two workers can quickly and safely dismantle the shaft without lifting equipment.

*Higher Transmission Efficiency

Synchronous belt transmission to obtain higher transmission efficiency.

*Longer Scrapers

The 762mm long scrapers makes chilling tube durable

*Seals

Product seal adopts silicon carbide wear-resistant ring balanced design, rubber O ring use food grade silicone

*Materials

The product contact parts are made of high-quality stainless steel, and the crystal tube is made of carbon steel, and the surface is plated with a hard layer

*Modular Design

The modular design of the product makes

the maintenance cost lower.

Technical Specification

| Technical Spec. | Unit | SPA-1000 | SPA-2000 |

| Nominal Capacity(Puff pastry margarine) | kg/h | 1000 | 2000 |

| Nominal Capacity(Shortening) | kg/h | 1200 | 2300 |

| Main Power | kw | 11 | 7.5+11 |

| Dia. Of Main Shaft | mm | 126 | 126 |

| Annular Space | mm | 7 | 7 |

| Heat Transmission Surface | m2 | 0.7 | 0.7+0.7 |

| Tube Volume | L | 4.5 | 4.5+4.5 |

| Inner Dia./Length of Cooling Tube | mm | 140/1525 | 140/1525 |

| Rows of Scraper | pc | 2 | 2 |

| Rotating Speed of Main Shaft | rpm | 660 | 660 |

| Max.Working Pressure (material side) | bar | 60 | 60 |

| Max.Working Pressure (medium side) | bar | 16 | 16 |

| Min. Evaporating Temp. | ℃ | -25 | -25 |

| Processing Pipe Size | DN32 | DN32 | |

| Dia. of Refrigerant Supply Pipe | mm | 19 | 22 |

| Dia. of Refrigerant Return Pipe | mm | 38 | 54 |

| Hot Water Tank Volume | L | 30 | 30 |

| Power of Hot Water Tank | kw | 3 | 3 |

| Power of Hot Water Circulation Pump | kw | 0.75 | 0.75 |

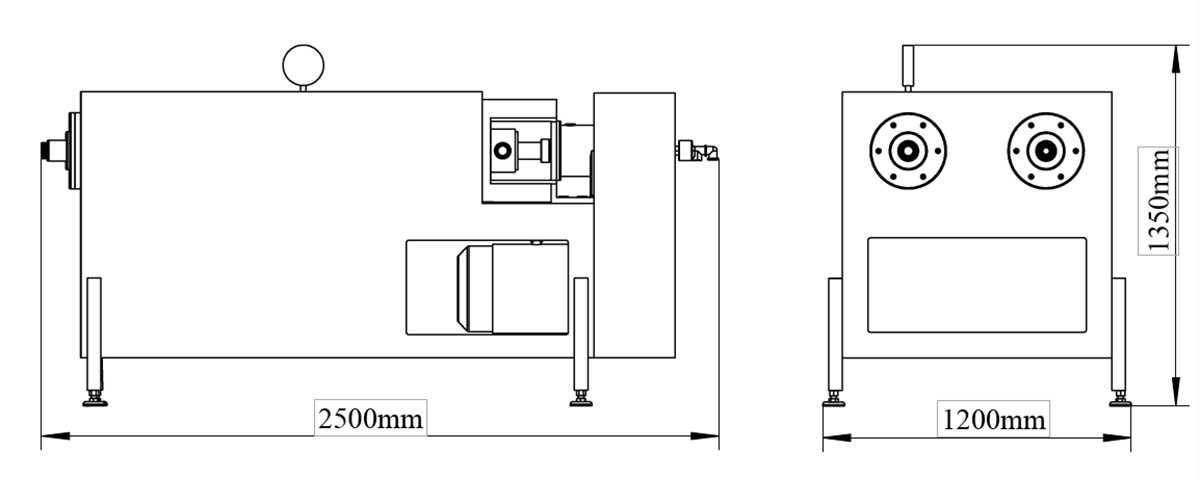

| Overall Dimension | mm | 2500*600*1350 | 2500*1200*1350 |

| Gross Weight | kg | 1000 | 1500 |

Equipment Pictures

Equipment Drawing

Site Commissioning