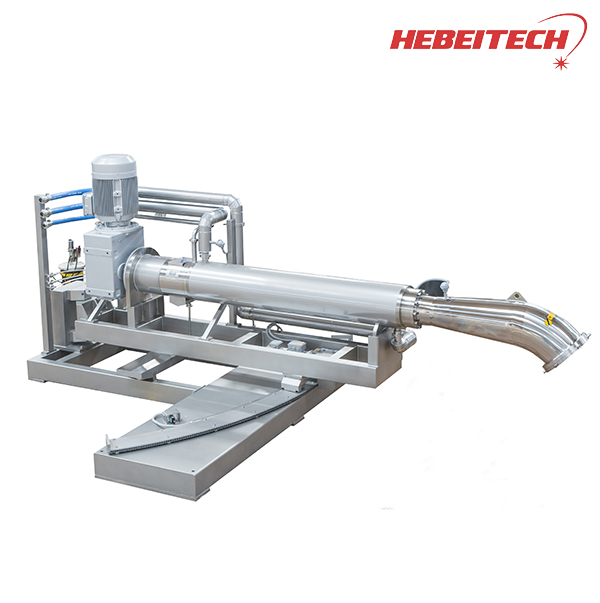

Scraped Surface Heat Exchanger Model SPK China Manufacturer

General Description

A horizontal scraped surface heat exchanger that can be used to heat or cool products with a viscosity of 1000 to 50000cP is especially suitable for medium viscosity products. Its horizontal design allows it to be installed in a cost-effective manner. It is also easy to repair because all components can be maintained on the ground.

- Coupling connection

- Durable scraper material and process

- High precision machining process

- Rugged heat transfer tube material and inner hole process treatment

- The heat transfer tube cannot be disassembled and replaced separately

- Adopt Rx series helical gear reducer

- Concentric installation, higher installation requirements

- Follow 3A design standards

It shares many interchangeable parts like bearing, mechanical seal and scraper blades. The basic design consists of a pipe-in-pipe cylinder with inner pipe for product and outer pipe for cooling refrigerant. A rotating shaft with scraper blades provides the necessary scraping function of heat transfer, mixing and emulsification.

Technical Specification

1. Annular Space : 10 - 20mm

2. Total Heat Exchanger Area : 1.0 m2

3. Max Product Tested Pressure : 60 bar

4. Approximate Weight : 1000 kg

5. Approx Dimensions : 2442 mm L x 300 mm dia.

6. Required Compressor Capacity : 60kw at -20°C

7. Shaft Speed : VFD drive 200 ~ 400 rpm

8. Blade Material : PEEK, SS420

Site Commissioning